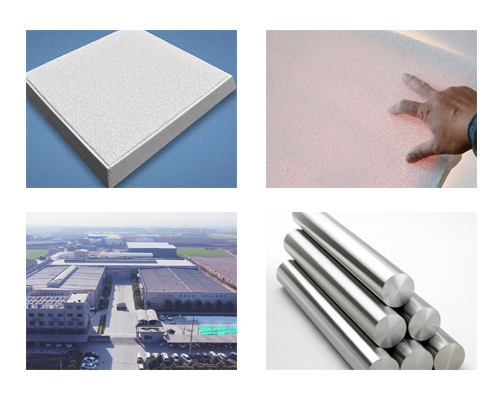

AdTech provides an alumina filter for molten aluminum, which has high thermal shock resistance, high corrosion resistance, sufficient strength, economical production, is more environmentally friendly than existing technologies, and has low density. The ceramic foam filter is proven to resist the chemical attack of molten aluminum alloy. The ceramic foam filter is light in weight and preferably has a density of about 0.25-0.40 g/cc.

Alumina ceramic foam filter is mainly for filtration of molten aluminum and aluminum alloys in foundries and cast houses. With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

The earliest commercial ceramic foam filters were based on chromium-alumina particulate material, aluminum orthophosphate binder and bentonite/kaolin additives to enhance slurry rheology. Chromium-alumina particles are relatively expensive and pose potential disposal problems due to concerns that potential hexavalent chromium is a known carcinogen. Subsequently, the chromium-alumina formula was replaced by a “full alumina” formula, which contained aluminosilicate fibers and mineral colloids and clay additives, while still using the aluminum orthophosphate binder system of the chromium-alumina filter. This “all alumina” filter formulation has subsequently been widely used worldwide and has become the “industry standard” for ceramic foam filters used in aluminum cast houses for more than 25 years.

Although aluminum phosphate combined with alumina foam filters are widely used, this filter formulation has several obvious disadvantages. The aluminophosphate filter has poor thermal shock resistance and must develop lateral compression failure due to the tendency to lose strength during use of the attack. Aluminophosphate bond; it has poor resistance to chemical attack and erosion of the filter structure body. In addition, the used filter generates phosphine gas, which complicates the processing.

For anyone familiar with the refractory materials used to contain molten aluminum and its alloys, the use of alumina particles in ceramic foam filters seems to be an obvious choice. Alumina is relatively chemically inert in molten aluminum, and it is a common alloy, including those containing magnesium. It is also widely used as a particulate material in refractory materials used in furnaces to melt and maintain molten aluminum alloys.