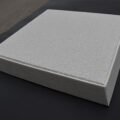

30PPI Ceramic Foam Filter is the most commonly used molten aluminum filter in the aluminum casting industry. Ordinary aluminum casting usually uses 10-40ppi ceramic foam filters. Aviation and high-quality aluminum materials usually use 30-60ppi ceramic foam filters. For high-quality aluminum casting, aluminum foundry usually uses 30PPI and 50PPI Ceramic Foam Filter two-stage molten metal filtration.

Ceramic Foam Filter has excellent resistance to attack and corrosion from molten aluminum. Ceramic Foam Filter can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

AdTech keeps focusing on the manufacture of metallurgical material. AdTech engineers work with aluminum operations to determine the best filtration methods and products for their needs. Our products are in use around the world in automotive, aerospace, rail transportation and high-tech manufacturing. We have been always dedicating to the customers with qualified products and professional service.

AdTech specially designed Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. They are manufactured with porosities varying from 10 to 60 pores per inch (PPI). Also, combo sets are made in 20-30 PPI and other selections are possible. Different sizes and custom-made filters are manufactured according to specifications.

Our alumina ceramic foam filter uses good portiforium foam and high purity ceramic as raw material, can remove the non-metal solid mixture from molten aluminum and aluminum alloy effectively in your aluminum casting industry. Using the right High-Temperature Materials will affect your productivity in a positive way!

Alumina Ceramic Foam Filters mainly for filtration of aluminium and aluminium alloys in foundries and cast houses. With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.