With the advancement of aluminum alloy processing technology and the development of aluminum alloy agent purification technology, the preparation of flux and its performance requirements show some new characteristics, which not only put forward higher requirements for the purification effect of the flux, but also the purification effect of the flux. Put forward higher requirements. Higher requirements are put forward on the flux itself. Quality also provides new insights.

The purification treatment of the former aluminum melt has higher and higher requirements for purification. The complex structure of the aluminum alloy agent composition increases the possibility of the second contamination of the aluminum melt and the environment by the flux itself. Under dynamic conditions, the configuration of the flux composition is as simple as possible. This is the only way to solve the side effects of the flux use process itself.

Refining agents are usually used to improve refining efficiency, and other compounds such as nitrates, sulfides, fluorides and rare earth compounds are usually added to them. The main self-reaction of graphite and nitrate in the refining process is thermal decomposition reaction, which will produce NOx, CO2, CO, O2 and other gases, and the effect of degassing and slagging is very poor. Fluorides usually include NaF, AlF3, CaF2, MgF2, KF, Na3AlF6 and Na2SiF6, etc., and NaF and AlF3 series fluorides are the most economical additives.

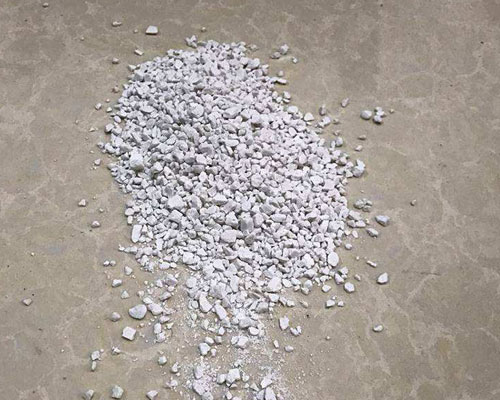

In the flux based on NaCl-KCl and KCl-MgCl2, adding an appropriate amount of fluoride can easily remove the oxide film at the flux-aluminum interface, so that the stable metal film at the interface is easy to rupture, and the inclusions are transferred to aluminum In the flux. The liquid interface migration process is easy to proceed. Add a small amount of cryolite to the refining agent, so that the molten cryolite can completely wet the alumina and enhance the adsorption capacity of alumina inclusions. However, from the standpoint of separation from molten aluminum and thermodynamics, the amount of fluoride added should not be too much, usually less than 10% is better.