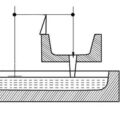

In the aluminum industry, the flow control box does not stick to aluminum. It is mainly used in conjunction with a flow control device to control the uniform flow of molten metal in the casting-rolling forming process. The flow control box is used between the split nozzle of the matching casting nozzle and the active flow groove, and is used for the crystal forming of the aluminum foil strip in the casting and rolling production line.

The aluminum flow head box adopts high-silicon melt molding technology, which has certain corrosion resistance, non-stick aluminum, and no pollution to aluminum liquid. The flow control box does not use high-silicon melt molding technology, has good thermal insulation performance, smooth surface, good wettability, and can be used multiple times. It solves the traditional one-time control flow box replacement and effectively saves the cost of traditional materials by 3-4 times.

The aluminum flow box has an automatic steady flow control function, which replaces the traditional manual flow control, effectively reduces labor costs and improves the flow stability of liquid metal.

Aluminum liquid level control technology is indispensable in aluminum alloy casting technology. An unstable liquid level can easily cause cold separation on the surface of the ingot. For alloy plates with strong notch sensitivity, cold insulation may directly cause side cracks. Therefore, a stable liquid level is an important condition to avoid the formation of cold barriers. In addition, a stable liquid level can also reduce the formation of coarse particles and thick columns. When the casting speed is constant, the smooth control of the liquid level in the crystallizer means that the supply flow from the nozzle to the crystallizer is very uniform, so that the temperature of the melt in the liquid cavity is uniform, and uneven crystallization is reduced during the crystallization process. The generation of particles reduces the formation of coarse crystals and coarse columnar crystals, thereby improving the internal quality of the slab. The use of aluminum liquid level control enables the aluminum liquid level control technology not only to realize low-level casting, but also to improve the inherent quality and surface quality of the ingot. In order to better measure the on-site aluminum water level and facilitate manual adjustment, the aluminum water level control installation height is very strict.