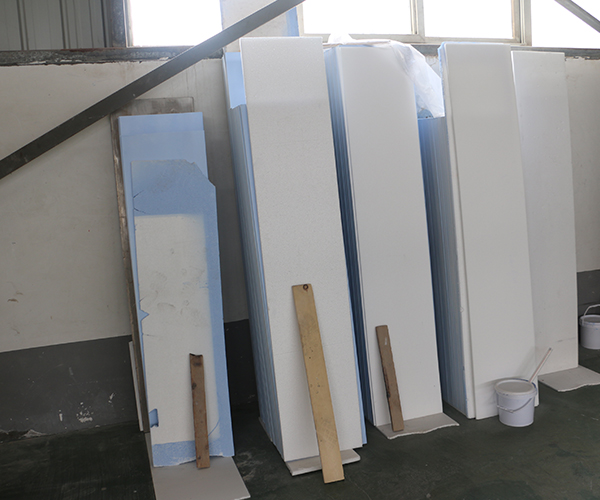

Aluminum water casting nozzle, also known as caster tip, is a ceramic composite product developed and produced by AdTech. It is composed of ceramic fibers and inorganic ceramic materials. It has the advantages of moderate elasticity, small deformation and long service life. It can effectively prevent the aluminum melt from corroding the cavity of the casting nozzle, thereby providing an effective guarantee for the quality of the cast steel plate. Various types of flow-supply pouring nozzles can be made according to customer requirements.

The ceramic fiber casting nozzle plate is a key component of the aluminum continuous casting machine, which directly affects the quality of the aluminum plate and the yield of production. Caster tips can be divided into many types according to different casting machines. The aluminum silicate casters produced by our factory are made of ceramic fiber and some other refractory materials.

Aluminum Water Casting Nozzle Features:

1. Excellent thermal insulation.

2. High bending and compressive strength.

3. Excellent thermal shock resistance.

4. The surface is smooth and does not stick to aluminum.

5. Good insulation and no deformation.

The ceramic fiber casting nozzle has a smooth coating on the opening surface and working surface, which can resist the corrosion of molten aluminum and ensure the purity of the aluminum plate. Castings have excellent non-wetting properties, low thermal conductivity, high temperature stability, uniform density, smooth surfaces and precise tolerances. They are excellent products for continuous aluminum strip casting.

Ceramic Fiber Castertip has excellent non-wetting properties, low thermal conductivity, high temperature stability, uniform density, smooth surface and tight tolerances. It is a high-quality product for aluminum strip continuous casting.

The liquid aluminum casting tip can effectively prevent the molten aluminum from corroding the casting nozzle and avoid carbonization; the fracture structure is a fine and uniform layered fiber structure to prevent the existence of flocculent structure; the working surface coating is uniform and smooth to prevent particle cracks and coating shedding The occurrence of this provides a guarantee for high-quality cast slabs.