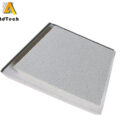

The aluminum melt filter box is the last process for molten metal purification treatment, which is very important for product internal quality control.

In the production process of aluminum ingots, the purity of molten aluminum is related to metallurgical quality. In traditional aluminum alloy casting, the use of ceramic foam filter plate is the most common method to remove impurities in the molten aluminum. Usually, the ceramic foam filter plate is directly placed in the molten aluminum flow channel. Due to the large gap between the filter plate and the flow channel, the impurities can still bypass the filter plate through the gap, which fails to meet the filtering requirements. If the ceramic foam filter plate is used directly in the flow channel, the aluminum liquid will have a greater impact on the filter plate, which will seriously affect the service life of the filter plate.

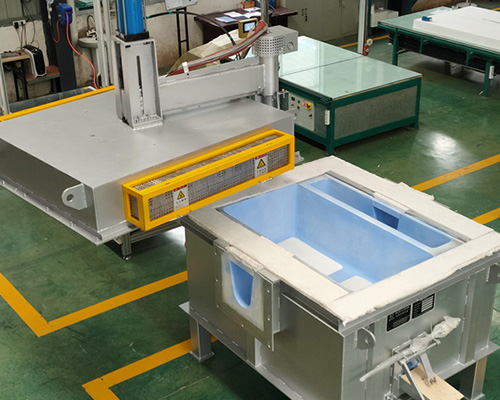

AdTech provides an aluminum melt filter box, which includes a box body and ceramic foam filter plate. The molten aluminum passes through the box, the ceramic foam filter plate is embedded in the filter box, and the filter plate is sealed with a gasket. The impact of molten aluminum on the filter plate is small, which prolongs the life of the filter plate; a heater is installed in the filter box to heat the molten aluminum to ensure the fluidity of the molten aluminum.

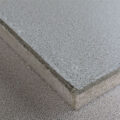

The ceramic foam filter plate is the last process in the purification treatment of aluminum melt, and it is particularly important to choose a suitable ceramic foam filter plate. We have conducted in-depth research on the application of foam ceramics. At present, the application of nanotechnology to the foam ceramic filter plate has successfully improved the filtration accuracy and service life of the foam ceramic filter plate, while effectively reducing the sintering temperature, energy-saving, and emission reduction.

Due to the instability of raw materials in the market and the influence of weather, climate, humidity, and temperature changes, we will continue to improve the filtration accuracy, use performance, and process stability of the foam ceramic filter plate.