The molten metal enters the gap between a pair of water-cooled continuous caster rolls through a pair of feeding nozzle member funnels. The axes of the rollers of the continuous caster are parallel, and the casters are driven by the continuous rollers in the metal moving direction.

The molten metal comes out of the downstream edges of the pair of feeding nozzle members, and the cross-section is enlarged to engage with the surfaces of the pair of continuous casting rolls. The water-cooled continuous casting roll absorbs heat from the molten metal. Freezing occurs in a narrow area upstream of the gap between the continuous casting roll and the downstream edges of the pair of feed nozzle members. The solid metal moves downstream and passes through the gap between a pair of slowly rotating continuous casting rolls, and the thickness is reduced, and its thickness is equal to the gap between the continuous casting rolls. The continuous metal sheet leaves the pair of continuous caster rolls, opposite to the side of the pair of feed nozzle members that feed the molten metal.

The downstream edges of the pair of molten metal feed tip nozzle members are spaced apart to provide a continuous opening extending along the length of the caster roll, the total length of the opening roughly corresponding to the desired width of the sheet being cast. The conventional flared end baffle closes the two ends of the caster feeding nozzle and helps determine the width of the thin plate to be cast. The width of the plate prepared during the manufacturing process may change from time to time, and the maximum value depends on the length of the continuous casting roll. The width is usually 11/2 to 2 meters. Therefore, the feed nozzle member is made of multiple segments, each segment typically extending 15 cm along the length of the caster roll. Therefore, a greater or lesser number of segments can be assembled to form a feed nozzle member having a desired width for continuous caster rollers.

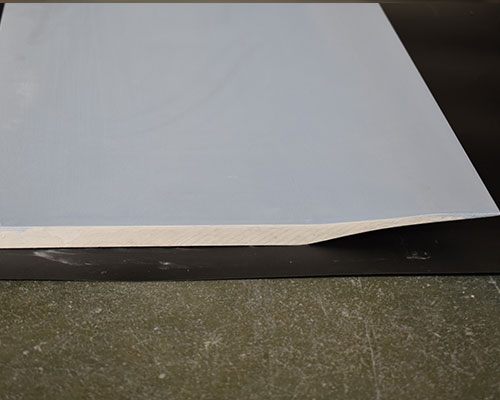

AdTech casting tips are dimensionally stable, thermal shock resistant and do not cause outgassing. A ceramic caster feeding nozzle can effectively protect the quality of the cast and rolled coils. It is best used together with boron nitride paint. AdTech caster tip is used to produce high-grade aluminum alloy. Ceramic fiber caster tip consists of an alumina ceramic liner and castertip ear. AdTech offers all of the component pieces required for continuous casting tip assemblies such as end dams, spacer boards, internal baffles, boron nitride coatings.