Feed caster nozzle often explodes due to the accumulation of gas in the nozzle cavity during casting and rolling.

By drilling holes on the surface of the caster nozzles and using far-infrared nozzle baking technology, the possibility of gas accumulation in the nozzle chamber of hard materials can be greatly reduced.

The feed caster nozzle is a key component that distributes and transports molten aluminum directly to the roll gap in the process of casting and rolling.

The rationality and practicability of its structure and the selection of nozzle material are very important for normal production, stabilizing various process parameters and improving the quality of cast rolling slab.

Combined with field application, how to improve the production and baking method of casting nozzle, reduce the occurrence of plate cleaning bar defects, and avoid the phenomenon of nozzle suction explosion in the process of erection.

What problems do you encounter when casting aluminum strip castings?

The gas in the cavity of casting tips and nozzle plate cannot be removed quickly after heating. The occurrence of strip defects.

In addition, the accumulation of gas in the internal cavity can cause explosion during installation. In severe cases, the oxide film will roll up and produce slag stripes, or lead to casting lip defects, which can not continue production.

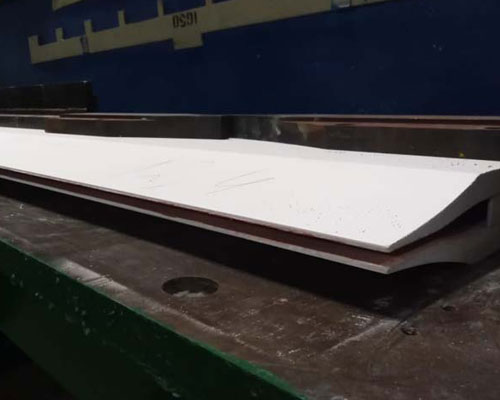

The surface of hard material nozzle plate is 23mm, which is the densest layer. Therefore, even if the surface is punched, it is conducive to gas collection and diffusion. The diameter of the punch hole is 1 “2mm and should be evenly distributed on the surface of the nozzle plate. The position of the hole should not be close to the arc surface.

Please use far infrared drying technology to dry castertip before use.

Before assembling caster nozzle, use far-infrared drying oven for drying treatment, which can remove the internal moisture of castertip material and greatly reduce the rate of castertip explosion caused by water vapor accumulated during installation.

Far infrared drying oven has the advantages of good heating effect, high heating efficiency and convenient operation. It is obtained by practical application and collecting a large amount of production data. After far-infrared drying technology, the possibility of gas accumulation explosion or tube cavity blockage is greatly reduced.