In the process of heating and smelting, solid and liquid aluminum have a certain ability to absorb H₂, 0₂, and other gases. This property of aluminum is called gettering, and it is one of the important melting characteristics of metals. Practice has proved that the gas present in aluminum will adversely affect the performance of […]

In the smelting process of aluminum and aluminum alloys, hydrogen and oxidized inclusions are the main substances polluting the aluminum melt. Aluminum easily forms A1202 or sub-alumina (Al2O and A10) with oxygen. At the same time, it is also very easy to absorb gas (H) whose content accounts for 70-90% of the total gas in […]

Fluxes Used in Aluminum Liquid can also effectively remove the oxide film on the surface of the melt and improve the degassing effect. Fluxes used in aluminum liquid are generally composed of alkali metal and alkaline earth metal chlorides and fluorides. The main components of which are KCl, NaCl, NaF, CaF, Na3A1F6, Na2SiF6, etc. The […]

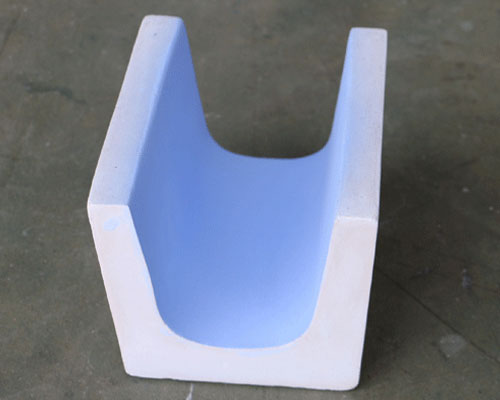

In the aluminum processing industry, it needs equipment to re-injected liquid metal from smelting furnaces to holding furnaces. So that the liquid metal can flow between the equipment according to the process steps. The current general practice is to arrange a flow channel between the devices, the flow channel is connected to the aluminum liquid […]

Boron nitride coating can improve the performance of refractory materials, it is mainly used to the surface of the refractory material or penetrating the working layer of the refractory material. The boron nitride paint has boron nitride and boron oxide. The particle size of boron nitride is between 20 microns and 50 microns, and the […]

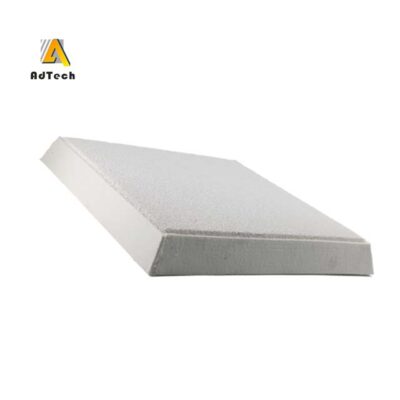

With the development of the metallurgical industry, aluminum foundries pay more and more attention to the purity of aluminum. The CFF filtering method is currently the most widely used and most economical filtering method in the world. So do you know the Ceramic Foam Filtration Mechanism, let’s understand it together. CFF Filtration Mechanism Through screening, […]

When these inclusions appear in the final cast product after the molten aluminum is solidified, they cause the final aluminum product to be less ductile or to have poor finishing characteristics. Therefore, it is important to remove entrained solids from the molten aluminum before it is cast into a solid body. In general, the ceramic […]

Metal casting components are found in 90 percent of manufactured goods and equipment, from critical components for aircraft and automotive industry to home applications. However, molten metal used to produce metal casting in practice generally contains impurities and inclusions, which are deleterious to final cast metal products. Currently, the CFF filtration technique by using ceramic […]

To pour the molten aluminum from melting or holding furnaces for aluminum casting, some units use tap hole block, which is sealed with Refractory Tap Out Cone. Refractory Tap Out Cone are divided into several names: Refractory Cone, Tap Out Cone, Refractory Ceramic Fiber Cone, Refractory Ceramic Fiber Hard Tip, Tap Hole Cone, Tap-Out Cone, […]

Refractory Fiber Cone/Taphole/tap out cone is suitable for non-ferrous metal melting furnaces. Description: Cone-shaped, Off white color Material: Inorganic 1260 ceramic fiber, also called aluminosilicate fiber Purpose: To be used cover and protect taphole plugs used in furnaces for melting aluminum, magnesium, and zinc alloys. The refractory fiber cones are disposable and are recommended for […]