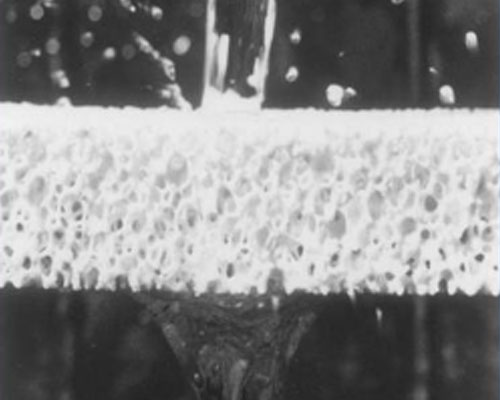

One method of removing gaseous impurities from metal melt is degassing. The physical process involves injecting flux gas into the melt. Hydrogen enters the purge bubble by diffusing through the melt and entering the bubble. In the bubble, the hydrogen adheres to the surface of the bubble and is adsorbed into the bubble itself. Then, […]

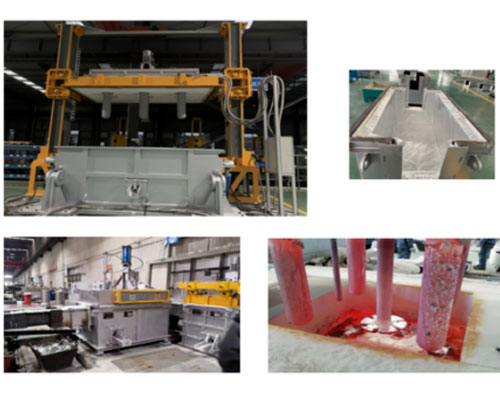

AdTech has specially developed online degassing and filtering equipment for molten metal, especially the improvement of degassing and filtering of aluminum. The degassing system and CFF filter equipments are located between the melting furnace and the casting platform, and mainly used to remove hydrogen and inclusions in the molten aluminum. Molten metal, especially molten aluminum […]

In the molten aluminum degassing process, degassing equipment uses inert gas with a purity of 99.99% to remove hydrogen and slag from molten aluminum. The rotating silicon nitride rotor breaks the ammonia (or argon) blown into the aluminum water into a large number of dispersed bubbles and disperses them in the molten metal. Bubbles in […]

Molten aluminum and its alloys degassing refining is an important steps before casting. Degas to reduce hydrogen content. Online degassing is a popular method, it is carried out with the help of SNIF, LARS, and other online degassing refining equipment. Refine the grain to improve the microstructure of the cast product. It involves adding a […]

The remelting of foil scrap has presented an especially difficult problem because of the extreme thinness of the metal sheet compared to area, and the resultant ease of oxidation in the melting furnace. The melt obtained from reclaiming foil scrap, therefore, contains a large number of oxide particles and occluded gas. To render the metal […]

After adding alloying elements to molten aluminum, the alloy melt needs degassing and filtering. Alloying elements are added to molten aluminum, and the alloying elements are highly reactive and tend to increase the oxidation rate of the melt. The addition of these highly reactive elements occurs after all other major alloy additions are completed, after […]

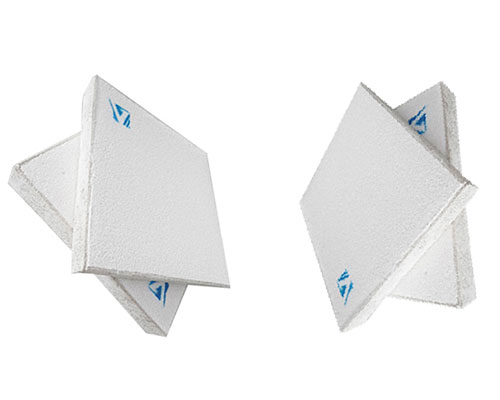

Cast Metal Filtration can remove impurities with a fineness of up to micrometers, and the cast aluminum liquid filter can effectively remove various inclusions in the aluminum water. Cast Metal Filtration can make aluminum horizontally smooth laminar flow, which is conducive to washing, good mechanical strength and chemical stability, and superior aluminum water erosion resistance. […]

Generally, impurities such as those mentioned, are removed from the aluminum-silicon alloy in separate steps. Usually, the hydrogen gas is removed followed by the removal of oxide impurities. AdTech online degassing system and CFF filtering equipment are used for hydrogen gas and oxide impurities removal. Online degassing and filtering systems are installed between the furnace […]

In the world’s non-ferrous metal production, the annual output of aluminum has always been the first, far exceeding other non-ferrous metals. The amount of refractory materials consumed by the aluminum industry each year is far greater than the total amount of refractory materials consumed in the smelting of copper, lead and zinc. According to the […]

Filtration is the most effective and reliable method to remove non-metallic inclusions in the aluminum melt. There are several filtering methods, the best result is Metal Foam Filter. Metal Foam Filter is widely used worldwide due to its convenience, good filtering efficiency and low price. In developed countries, 50% of aluminum alloy melts are filtered […]