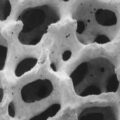

As we all know, ceramic foam filter products play a very important role in the aluminum liquid purification system.

Aluminum and its alloys are easy to oxidize and absorb gas during melting and pouring, which makes it easy to form inclusions in molten aluminum and form pores during solidification, thereby affecting the quality of castings and restricting the application of aluminum alloys.

The inclusions in aluminum and its alloy liquids are mainly oxidized inclusions, and their existence will cause difficulties in dehydrogenation of liquid aluminum and increase in defects such as pore inclusions, which in turn will cause the mechanical properties of aluminum alloy castings to decrease and the reliability of the aluminum alloy castings to decrease. Therefore, the removal of inclusions in aluminum and its alloys is of great help to improving the mechanical properties of aluminum alloys.

There is an interaction between the inclusions in the aluminum melt and the hydrogen. The presence of inclusions makes it difficult to remove hydrogen from the aluminum melt. Only by removing the inclusions in the aluminum melt, can the hydrogen be reduced to a lower level and at the same time prevent the aluminum liquid from absorbing hydrogen.

The ceramic foam filter can effectively remove the large inclusions in the molten aluminum, effectively reduce the size of the micro inclusions, and improve the surface quality and product performance, improve the effect of the microstructure and increase the yield. As long as it is used for precision casting of aluminum alloys such as aviation and transportation.

AdTech ceramic foam filter adopts a three-dimensional network structure. The organic carrier is connected with the pores to invade the special ZrO2 high-quality melt with special thixotropy. The automatic extrusion technology of the four square correct center distance is adopted to make the slurry evenly coated on the foam On the bubble. Carrier. The frame is baked and cured at a high temperature of 1680°C, and has a bulky cotton body seal.

The specifications of the Ceramic Foam Filter Products provided by our company: 7in, 9in, 12in, 15in, 17in, 20in, 23in, 26in. The pore size of ceramic foam filter: 20/30/40/50/60 (PPI).