The experience of the aluminum processing industry has proved that the continuous casting rolling production process can produce double zero foil with high surface quality, structure and performance in line with the standard requirements.

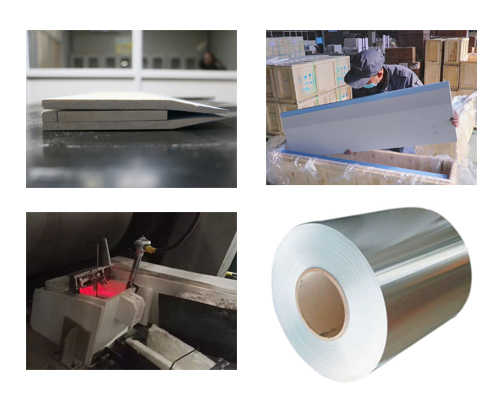

There are three process routes for double zero foil production with the cast-rolled strip: The first process is to cold-roll the cast-rolled strip to 0.6mm and perform intermediate annealing; the second process is to cold-roll the cast-rolled billet To 1.0-2.0mm, and then cold-rolled to 0.3-0.6mm, two intermediate annealing is performed; the third process is to cold-roll the cast-rolled billet to 0.4mm without intermediate annealing, and finally roll the double zero foil.

The process of producing aluminum foil with cast-rolled strips is the shortest process at present. Not only has the equipment investment been greatly reduced, but the production cycle has been significantly shortened, and the yield and labor productivity have been greatly improved. Therefore, the cost can be reduced, and the economic benefits are very significant. Some quality indicators of aluminum foil are better than those produced by hot-rolled billets.

Because of the low flow rate and low output of continuous casting and rolling production, plate CFF filtration is a more suitable filtration method. Continuous casting and rolling production has high requirements for the quality of aluminum alloy melt, otherwise, defects such as uneven grains and streaks will appear at the mouth of the casting lips.

Purifying the molten aluminum outside the furnace through the ceramic foam filter plate is an effective method to improve the cleanliness of the molten aluminum. The ceramic filtering process can effectively remove various inclusions in the molten aluminum with a fineness of micrometers, reduce the influence of inclusions on the quality of the cast-rolled billet, and provide a basic guarantee for obtaining high-quality cast-rolled billets. The clean quality of the ceramic filter plate to the molten aluminum is directly related to the amount of molten aluminum filtered by the ceramic filter plate. Therefore, in order to be able to process high-quality ultra-thin aluminum foil, it is necessary to select as clean aluminum liquid as possible to produce cast-rolled blanks.