The correct selection of foundry ceramic filters can improve the cleanliness of aluminum melt.

The selection of foundry ceramic foam filters is first determined according to the impurity content in the aluminum melt, the melt transfer flow rate and the quality requirements of the final cast product.

There are many impurities and the quality of the casting products is average. A foam ceramic filter plate with larger mesh can be selected, and a glass cloth coarse filter is added in front of the filter plate. For semi-continuous casting, first use glass cloth to filter coarsely, which can intercept the slag when the eye is opened and the slag washed down by the launder to prevent clogging of the filter plate.

The quality requirements of the casting products are high, and the ceramic foam filter with a small mesh size, that is, a large mesh number, is selected.

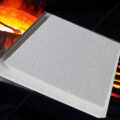

When choosing a better ceramic foam filter plate, you should also observe its color, take pictures of its bodies, and burn its objects.

The color is pure and free, indicating that the material is uniform. The hands are not sticky, indicating that the surface is not sprayed with adhesive and will not cause secondary pollution.

Holding the CFF filter plate with one hand and clapping the filter plate with the other hand, the ceramic slag is continuously dropped, indicating that the filter plate is inferior and will cause secondary pollution to the molten aluminum.

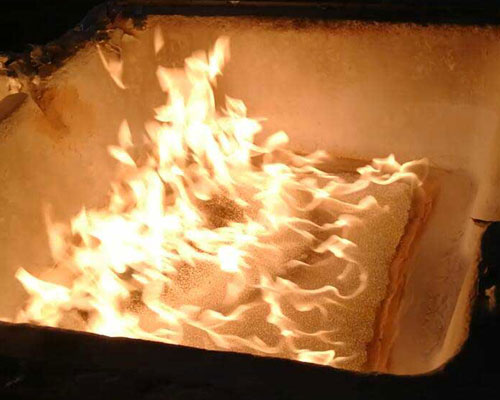

Use an open flame or electric heating to heat up and burn to red, immediately cool at room temperature without cracking and slag, indicating that it is a good filter plate.

When purchasing ceramic foam filter plates, the effective specific surface area or porosity calculation of the foam should be carefully evaluated.

You can observe the uniform state of the mesh on the surface of the filter plate, and then open it to observe the uniform state of the mesh on the section. If possible, the porosity can be measured and calculated by the drainage method. The three-dimensional mesh is homogeneous and the porosity is relatively large. It is an excellent foam ceramic filter plate.