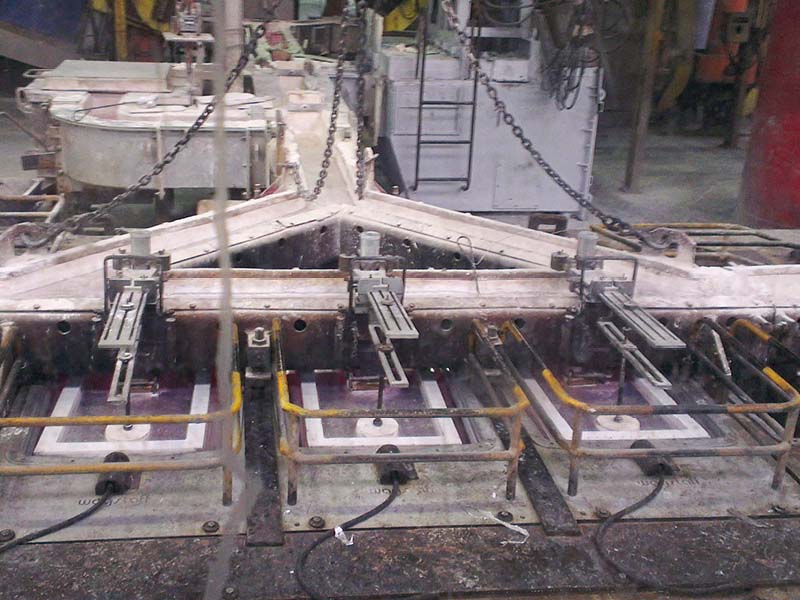

In the aluminum alloy casting process, the molten aluminum liquid is filtered by a filter bag and then cast into a mold for casting. Due to the fluctuation of the liquid level, the aluminum liquid enters the crystallizer and is filtered through the filter bag. Affected by the liquid level drop, when the liquid level enters the crystallizer, the aluminum liquid will roll over, and the slag generated or the presence of oxidized slag is brought into the crystallizer. In addition, the molten aluminum with impurities such as slag is directly ingot-shaped, resulting in a lower quality of the formed aluminum alloy product. Therefore, how to improve the quality of aluminum alloy ingots is a technical problem to be solved urgently by technical personnel in the aluminum industry. In order to solve this problem, AdTech has developed an impurity separation ring for aluminum alloy casting to improve the quality of aluminum alloy ingots.

Impurity Separation Ring

The slag dart ring for aluminum alloy casting includes a slag ring body and a hanging piece installed on the skim ring body. When aluminum alloy casting is required, the skim ring body is placed under the filter bag, and the hook is fixed to the outside to prevent the slag ring body from moving with the aluminum liquid.

By setting the impurity separation ring, the aluminum liquid filtered through the filter bag first enters the annular range formed by the slag ring body. The slag such as oxidized slag may be brought into the crystallizer. The slag ring body can intercept the slag such as oxidized slag. Let it flow out of the slag ring, and control scum like oxidation in the slag ring, thereby reducing the risk of aluminum alloy ingots being contaminated by slag. Therefore, AdTech’s slag ring can improve the quality of aluminum alloy ingots.

In order to prolong the service life of the impurity separation ring, it is preferable that the slag retaining ring is made of non-stick aluminum material and does not react with the aluminum liquid. Specifically, the surface of the slag retaining ring is provided with a boron nitride coating, which has high-temperature resistance, The advantages of corrosion resistance. Further, in order to better adapt to the crystallizer, the slag retaining ring is a rectangular ring, and the arc transition at the corner of the rectangular ring.