In the casting process of aluminum alloy, the aluminum water in the melting furnace needs to be injected into the crystallizer through the down injection pipe. However, during this process, the molten aluminum injected into the crystallizer will roll arbitrarily, resulting in oxidized slag inclusions. And it will result in uneven distribution of the molten aluminum in the crystallizer, which will seriously affect the quality of the product. In order to ensure that the aluminum level is slowly and evenly filled into the crystallizer, and improve the quality of the product. AdTech provides a distributing plate for crystallizer.

Distributing Plate for Aluminum Alloy

Therefore, in the process of injecting molten aluminum into the crystallizer, how to limit the molten aluminum to roll arbitrarily is the key problem for those skilled. The distributing launder for crystallizer can limit the arbitrary rolling of aluminum water, and ensure that the aluminum level is slowly and evenly filled into the crystallizer, thereby ensuring the quality of the product.

Distributing Launder for Crystallizer

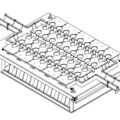

The distributing launder for the crystallizer includes a round tray, a ring plate, and several partition blocks. Among them, the ring plate is located above the round tray, and a ring gap is formed between the ring plate and the round tray. Several spacers are located in the ring plate, which are used to connect the ring plate and the round tray, and divide the ring gap into several arc gaps, and each arc gap is a drainage port. A plurality of drainage ports are provided on the peripheral for the crystallizer.

When injecting molten aluminum into the crystallizer, place the distributing launder for the crystallizer in the crystallizer. So that the outlet of the downcomer pipe is facing the center of the round tray, the aluminum water flowing out of the downcomer pipe enters the ring plate. Afterward, it will be constrained by a number of partitions and will not be able to roll arbitrarily. And the melton aluminum will be divided into a number of streams to the edge of the crystallizer under the constraints of the partitions and gradually fill the crystallizer.

The upper-end surface of the partition block is flush with the upper-end surface of the ring plate. The purpose of this setting is to further strengthen the restraint of the aluminum water entering the distributing launder, and prevent the aluminum water from flowing randomly through the partition block. Several partitions are evenly distributed around the center of the round tray. So as to ensure that the aluminum liquid can flow into various positions in the crystallizer, and ensure that the aluminum liquid is evenly distributed in the crystallizer.

The material of the round tray, ring plate and partition of the distribution launder is preferably graphite, and the density of graphite is less than that of aluminum water. Ensure aluminum water continuous diversion.