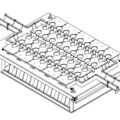

The distribution groove can limit the arbitrary rolling of the molten aluminum and ensure that the aluminum liquid level is slowly and evenly filled into the mold, thereby ensuring the quality of the product.

In the casting process of aluminum alloy, the molten aluminum in the melting furnace needs to be injected into the mold through an alumina ceramic tube. However, during this process, the molten aluminum injected into the crystallizer will randomly roll, causing oxidation and slag inclusions, resulting in uneven distribution of the molten aluminum in the crystallizer, seriously affecting product quality. Therefore, in the process of injecting molten aluminum into the mold, how to limit the random rolling of the molten aluminum and ensure that the molten aluminum is slowly and uniformly filled into the mold, thereby improving product quality is the key. Urgent solution.

AdTech provided distribution groove for aluminum casting molds. When injecting aluminum water, place the distribution launder in the crystallizer so that the outlet of the lower injection pipe faces the center of the circular tray. In this way, after the molten aluminum flowing out of the lower pipe enters the annular plate, it will be restricted by multiple gaskets and cannot roll arbitrarily. Under the restriction of several spacers, it will be divided into several streams, flow to the edge of the crystallizer, and gradually fill the crystallizer.

The distribution tank includes a circular tray that is located above the circular tray and forms an annular gap between the circular trays. It is located on the ring plate and used to connect the circular tray and the ring plate. A plurality of spacers divide the annular gap into a number of arc-shaped gap segments, and each segment of the arc-shaped gap is a discharge port. When injecting aluminum water into the crystallizer, place the crystallizer with partitions in the crystallizer so that the outlet of the lower spray pipe is directly located in the center of the circular tray. In this way, after the molten aluminum flowing out of the lower pipe enters the annular plate, it will be restricted by multiple gaskets and cannot roll arbitrarily. Under the restriction of several spacers, it will be divided into several streams, flow to the edge of the crystallizer, and gradually fill the crystallizer.