The present invention relates to an aluminum alloy casting, and particularly relates to casting slag ring for aluminium dross.

In the aluminum casting process, the molten aluminum molten glass after the bag filter into the mold cast molding.

The slag level by fluctuations in the molten aluminum into the mold, bag filter through glass, affected the level drop of the liquid level at the time of entering the mold, the molten aluminum will rollover occurs, or the presence of dross generated with into the crystallizer, while the slag with impurities such as aluminum ingot was directly formed, resulting in lower product quality molded aluminum alloy.

Therefore, how to improve the quality of aluminum alloy ingot, and is skilled in the art to be solved technical problems.

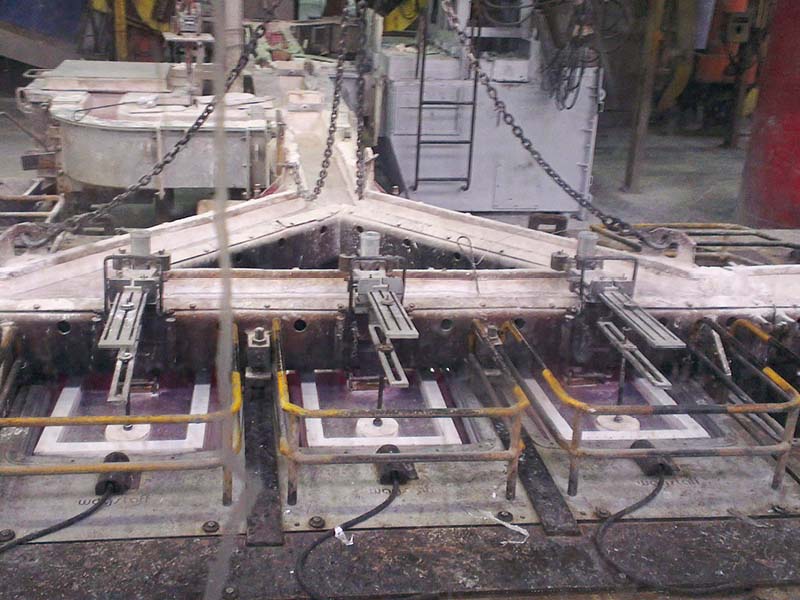

Adtech Slag Ring for Aluminium Dross

Aluminum alloy casting skim ring can improve the quality of the aluminum alloy ingot. To achieve the above object, the present invention provides an aluminum alloy casting ring slag, the slag comprising a body and a ring member mounted on said mount ring slag body.

Low density, relatively high strength, high light buoyancy, no pollution to molten metal, can be used multiple times, to meet the technical needs of aluminum alloy precision casting products such as aviation and transportation that produce high added value and high technical performance requirements.

BN coating treatment can achieve the effect of glaze, non-stick aluminum, no aluminum, completely avoiding the adverse effect of silicon melt on silicon.

Aluminum Casting Slag Ring’s excellent non-stick aluminum properties, while ensuring the interaction between the metal melts between different castings, the installation, maintenance and repair of the product is simple and convenient, the product has a service life of 3-6 months, improper use of artificial damage except.

Impurity Separation Ring Product Usage

The AdTech aluminum liquid slag ring is used in conjunction with the casting mold. By setting the slag ring, the filtered aluminum liquid first enters the annular range formed by the slag ring body.

The slag such as oxidized slag may be carried into the crystallizer, and the slag ring body may intercept the slag such as oxidized slag.

It is not allowed to flow into the inside of the slag ring, and the scum such as oxidized slag is controlled outside the alumina ceramic ring, thereby reducing the risk of the aluminum alloy ingot being contaminated by the slag.

Aluminum Casting Slag Ring Advantages

1. It has anti-scouring, non-flaking, smooth surface and no pollution to aluminum liquid.

2. It has the function of isolating oxidation slag and stable and safe casting.

3, the use of high flexibility, the metal shackle ring to the mold can be cast.

Impurity Separation Ring is a product used in aluminum moisture flow. It is very common in the manufacturing process of aluminum ingots and aluminum wheels, which can effectively remove the quality of impurities.

The distribution plate is a tool for contact with aluminum liquid before casting and during casting, so it is very important.

If it is combined with the aluminum liquid slag ring technology, it is considered to be the key to achieve the demanding quality standards of DC aluminum and aluminum alloy slab casting.