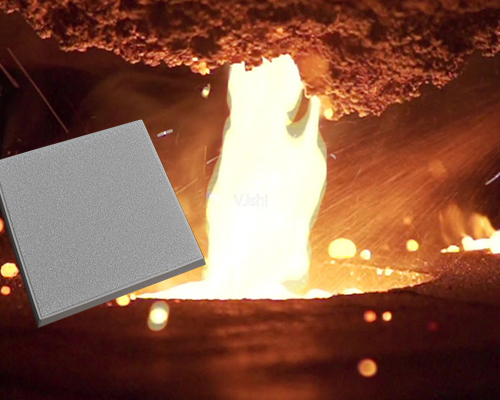

Ceramic Filtration System

The ceramic filtration system is resistant to the molten metal being filtered, and resistant to thermal shock, erosion and corrosion, allowing molten metal to flow through it. The ceramic filtration system has a barrier located immediately downstream of the ceramic foam filter. There are many uses for barriers. First, it collects the initial melt used to infuse the porous filter member and forms i ...

Read More…

Read More…

Ceramic Filter for Emirates Aluminium

The ceramic filter has become a necessary material for Emirates Aluminium. By applying the ceramic foam filter, the inclusions in the molten metal can be effectively removed or reduced, the purity of the molten metal can be improved, the surface of the cast metal castings can be smooth, the strength is improved, and the machining loss is reduced, thereby reducing energy consumption and increase la ...

Read More…

Read More…

Ceramic Filter for Ghana Aluminum

The use of ceramic foam filter plates to filter is currently the most effective way to remove inclusions for Ghana aluminum melt purification. The metal filter mesh and fiber cloth filter used by low-end customers can only remove large inclusions in the aluminum alloy melt. However, the inclusions below the micron level cannot be removed, and the metal filter will also pollute the aluminum alloy. ...

Read More…

Read More…

Ceramic Filter for Greek Aluminium

The main advantage of the ceramic filter for Greek Aluminium is to effectively eradicate the slag inclusions through the filter plate, and remove the micron-sized fine inclusions in the aluminum liquid. At the same time, because the ceramic filter plate filters out fine inclusions and reduces the effective number of crystal nuclei in the molten Greek aluminum, the molten aluminum nucleates and gro ...

Read More…

Read More…

Aluminum Alloys Smelting

The smelting of aluminum alloys has the characteristics of high heat consumption, easy oxidation, easy absorption of hydrogen, and easy absorption of impurity metals. (1) Consume a lot of calories. Although aluminum has a low melting point, it has a large latent heat of fusion, a large specific heat, a small blackness, and a strong reflection of heat. Compared with other commonly used metals such ...

Read More…

Read More…

Ceramic Foam Filter for Aluminum Water

The ceramic foam filter has an excellent filtering effect for aluminum water. It uses a three-dimensional structure to effectively remove oxidized inclusions and other non-metallic inclusions by blocking, capturing, and adsorbing. After the molten aluminum is filtered, the product quality will get satisfactory results. Aluminum products are widely used in areas that require high strength and elong ...

Read More…

Read More…

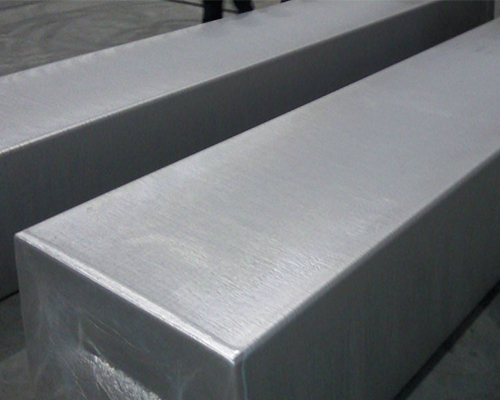

Scrap Aluminum Refining

In the production of aluminum alloy products, whether high-quality products can ultimately be produced depends mainly on the smelting and casting links. In the melting and casting process, hydrogen removal and impurity removal are the most important. For production lines that use scrap aluminum as raw materials to produce aluminum and aluminum alloys, online refining technology is the key. At pres ...

Read More…

Read More…

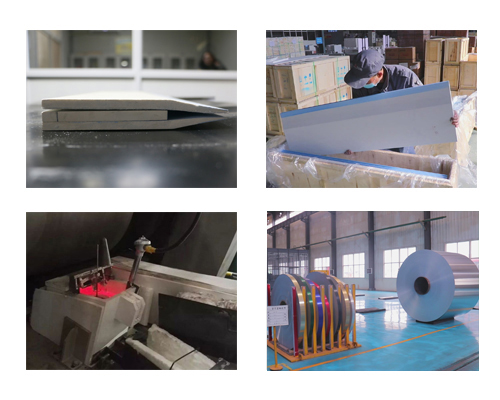

Aluminum Coil Rolling Process

In the aluminum coil rolled products industry, the continuous casting and rolling process have been widely used in the production of coils. In the world’s total output of aluminum plates, strips, and foils, hot-rolled billets are less than 20%, and lower-cost twin-roll continuous casting billets are more than 80%. Improving the quality of double-roll continuous cast-rolled aluminum coils can elimi ...

Read More…

Read More…

Cold Rolled Aluminum Process

Cold-rolled aluminum coil process usually refers to the processing of cast-rolled material. As for the aluminum coil casting and rolling process, relatively speaking, it may be much simpler. Aluminum ingot—aluminum liquid—furnace—cast-rolled coil, which is a conventional processing technology for raw cast-rolled materials. The hot rolled aluminum coil process is that its raw material is directly h ...

Read More…

Read More…

Casting and Rolling Process

Industrial Casting and Rolling Production Process: The molten metal in the stationary furnace is degassed and slag removed by the online degassing system. After the filtering system is filtered, the molten aluminum is stably fed into the casting nozzle through the liquid level control system. It is transported from the casting nozzle to the roll gap of the casting mill. After continuous casting an ...

Read More…

Read More…