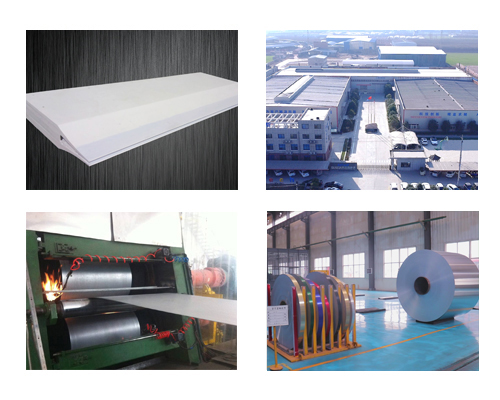

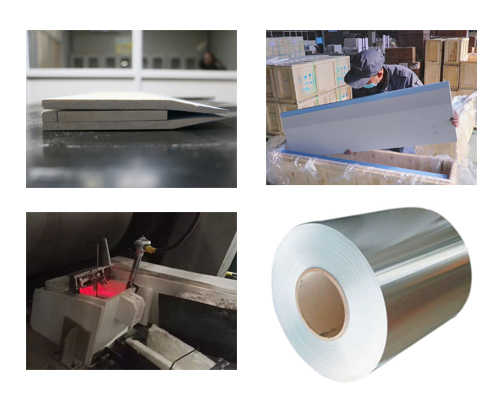

Ceramic Casting Tips

The ceramic casting tips are directly connected to the roll gap to fill the aluminum melt between the casting roll gaps steadily and evenly. It not only ensures the balance distribution of the aluminum liquid, but also the balance distribution of the temperature of the aluminum liquid, and does not cause pollution to the melt. This is very important to ensure the dimensional accuracy, microstructu ...

Read More…

Read More…

Double Zero Foil Process

The experience of the aluminum processing industry has proved that the continuous casting rolling production process can produce double zero foil with high surface quality, structure and performance in line with the standard requirements. There are three process routes for double zero foil production with the cast-rolled strip: The first process is to cold-roll the cast-rolled strip to 0.6mm and p ...

Read More…

Read More…

Degassing Filter Equipment

The degassing filter equipment and process can solve the oxidation inclusion, hydrogen content and alkali metal in the aluminum liquid, and improve the quality of the cast-rolled aluminum strip. This can eliminate defects such as horizontal grain chromatic aberration, crystal grain unevenness, and segregation streaks inherent in the continuous casting and rolling process. The production of high-gr ...

Read More…

Read More…

Head Box for Casting and Rolling

Head box for casting and rolling aluminum liquid level control plays an important role in ensuring the quality of the cast-rolled aluminum plates. In order to ensure continuous and stable aluminum plate casting, the amount of molten aluminum flowing into and out of the casting-rolling zone must be controlled in a balanced state, so that the aluminum melt in the front groove of the aluminum plate c ...

Read More…

Read More…

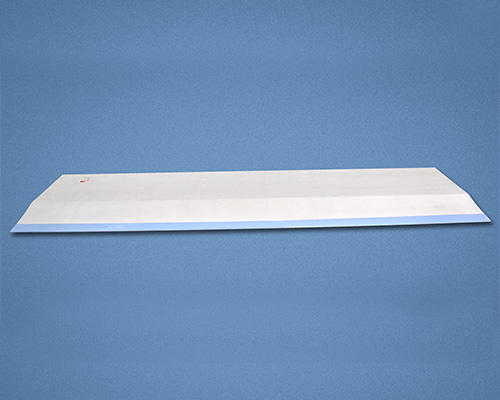

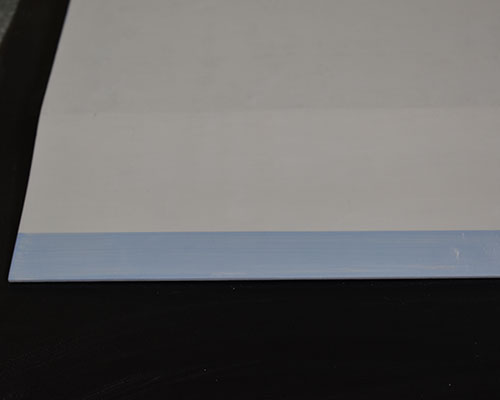

Casting Feed Nozzle

The function of the casting feed nozzle is to send the aluminum melt into the gap between the casting rolls. Therefore, the feed nozzle is a key component that directly distributes and transports the aluminum melt to the roll gap in the continuous casting and rolling process, and it is also the throat of the casting system. Its reasonable structure directly affects the product quality and output. ...

Read More…

Read More…

Feeding Tip and Nozzle

The feeding tip and nozzle provide the casting and rolling zone with a uniform, stable and continuous molten aluminum in the width direction of the plate, which is a prerequisite for the smooth progress of rapid continuous casting and rolling. Before the 1970s, the casting-rolling speed of the casting-rolling mill was low, the quality of casting-rolling was not high, and the requirements for the n ...

Read More…

Read More…

Ceramic Caster Tips

The ceramic caster tips, as the “throat component” that feeds the aluminum melt into the high-throughput continuous casting and rolling mill, play a very important role. Once problems such as clogging of the casting nozzle occur, the machine can only be shut down for replacement, resulting in production interruption, waste of manpower and material resources, and reduced production efficiency. High ...

Read More…

Read More…

Casting Tip for Conveying Aluminum Melt

In the aluminum strip double-roll casting and rolling production process, the casting tip is the most critical component for conveying aluminum melt. Its structure directly affects whether the molten aluminum can flow into the cast-rolling zone uniformly and steadily, which in turn affects the quality of cast-rolled slabs and even the stable and normal production of slabs. The casting-rolling proc ...

Read More…

Read More…

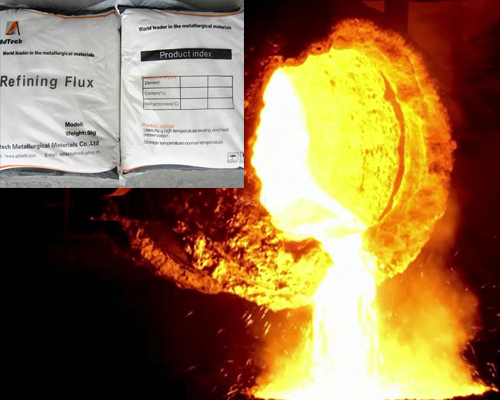

Flux for Volta Aluminium Melting

The Flux for Volta Aluminium Melting is mainly used to remove impurities. The essence of impurity removal is to use the difference in physical or chemical properties between the inclusion and the aluminum melt, so as to achieve the separation of the two, and achieve the purpose of impurity removal and hydrogen removal. The Flux for Volta Aluminium Melting mainly uses a mixture of NaCl and KCl as t ...

Read More…

Read More…

High Efficiency Purification Flux

A new type of high-efficiency purification flux replaces the traditional degassing flux, it is used for European aluminum smelter and foundry. The key to its high-efficiency impurity removal is to combine the three processes of aluminum melting, flux filtering, and flux gettering and impurity dissolution, and realize the whole process of melting. The new high-efficiency purification flux has low m ...

Read More…

Read More…