The research and development of high-quality aluminum alloy materials requires high-purity aluminum alloy raw materials. Therefore, it is an important topic for material science and technology workers to manufacture equipment that can deeply purify aluminum melt in the smelting process and develop a matching production process. Social development and progress today, aluminum alloy products have been widely used in people’s daily lives. The demand for high-end aluminum markets such as 3C products, automobiles, and high-speed railways has promoted considerable progress and development in aluminum alloy melt purification technology. Some private enterprises Invest a lot of money to purchase expensive production equipment in order to achieve deep purification of the melt, but how to optimize the configuration and layout to maximize the purification effect of the equipment is still a problem worthy of in-depth discussion.

The current general purify aluminum melt method is: after the smelting furnace, connect the degassing unit and the CFF filter box through the ceramic launder, and then transfer to the mold plate for casting. In this process, the launder is long, and the molten aluminum will cause slag and gas when passing through the launder and die plate, which will affect the quality of the molten aluminum.

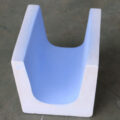

The purification system integrates degassing and filtering functions in a device to shorten the length of the flow trough as much as possible, thereby achieving the purpose of reducing the contamination of molten aluminum. The molten aluminum enters the degassing chamber through the flow trough. When the molten aluminum fills the degassing chamber to a certain height, the nitrogen enters the aluminum melt through the ventilating bricks, and the degassing and refining operation starts. quasi.

After degassing, the hydrogen content of the melt can be greatly reduced. After degassing, the molten aluminum flows to the filter chamber next to the degassing chamber. Put the foam ceramic filter plate in the filter box. Under the action of hydrostatic pressure, it passes through the filter plate, and after filtration is completed, it enters the flow tank through the water outlet. So far, the degassing and filtering operation is completed. After the above-mentioned steps are processed, a cast rod with a high degree of purification can be obtained.