In order to make aluminum and its alloys pure, with less gas and inclusions, the molten aluminum or aluminum alloy is refined (or called purification). The melting temperature of aluminum and most aluminum alloys is 700~750℃, and the casting temperature is slightly lower than the melting temperature. Melt refining is to remove gases, oxides and non-metallic inclusions in the melt, so that the melt can be purified. During the smelting of aluminum and aluminum master alloys, there is a strong tendency to produce pores, and it is also easy to produce oxide inclusions. Therefore, preventing and removing gas and oxidation inclusions has become the initial problem in the process of aluminum alloy melting and pouring. In the smelting process, in addition to the formation of Al2O3 with oxygen, it is also easy to absorb gas (H2). The hydrogen on the interface where the liquid metal contacts may be present in the atmosphere, or may be produced by the reaction between water vapor in the furnace gas and the components of the alloy. The purpose of refining and purification is to remove or minimize such inclusion gases to improve the degree of metal purification.

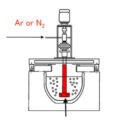

The refining and purification of aluminum alloy usually adopt the float method and the flux method. The method of adding the refining agent is: one is to press into the aluminum liquid with a bell jar, and the other is to blow into the aluminum liquid with an inert gas.

The inclusions in the molten aluminum not only come from the charge, but also from the oxide (Al2O3) produced by the reaction between aluminum and oxygen during the melting and pouring process. There is an oxide film on the surface of the molten aluminum. When it is close to the melting point, the thickness increases and the structure also changes; the side facing the molten aluminum is dense and has a protective effect on the molten aluminum, but the side facing the molten aluminum is loose Yes, a large number of tiny holes are formed inside and are filled with hydrogen, air, and water vapor. If the liquid film is stirred into the aluminum liquid, it will not only increase the inclusions in the aluminum liquid, but also increase the gas content in the aluminum.

Inclusions in aluminum often exist in the form of needles, blocks, etc., as inclusions, Al2O3 and the metal matrix have different elastic modulus and expansion coefficient, so stress concentration is easy to appear at the sharp corners of Al2O3. Therefore, these The place often becomes the source of material fracture and corrosion, which has a significant impact on the strength, fatigue resistance and corrosion resistance of the base material. Because the hardness of AM2O3 is very different from the hardness of a-Al base, in the plastic deformation of processed products, it strongly hinders the normal flow of a-Al, thereby significantly reducing the plastic deformation ability and fatigue life of processed products. When being strongly impacted by an external force, cracks are first generated where the inclusions exist, which often causes or accelerates the fracture of the material.