The degassing of aluminum is based on the principle that dissolved hydrogen gas will move from an area of high concentration (in the melt) to an area of low concentration (in the inert gas). The hydrogen gas disperses in the molten metal as it would if released in a confined space. It will maintain […]

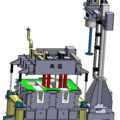

Improvement suggestions for domestic rotary jet online aluminum degassing unit.

The use of ceramic foam filter plates to remove impurities in the aluminum melt is currently a method widely used by aluminum processing manufacturers. It has the characteristics of strong adaptability, low price, safe and simple operation, and remarkable effect. However, there are many aspects of the filter plate that need to be paid attention […]

Rotary degassing method is currently the most widely used method of degassing and purifying molten aluminum. AdTech online degassing unit adopts this degassing method for molten aluminum purification. The principle of the rotary degassing method is to pass inert gas or active gas insoluble in the molten aluminum into the molten aluminum, or add chlorine […]

Degassing process in aluminum can be divided into two situations: one is the hydrogen removal process that can form hydrogen bubbles; the other is the hydrogen removal process that cannot form hydrogen bubbles. The degassing process in aluminum that can form hydrogen bubbles can be roughly divided into three stages: first, the formation of bubbles, […]

Rotary degassing purification method is a kind of bubble floatation method, and it is also the most widely used aluminum alloy melt purification method. Rotary blowing degassing purification method by degassing unit is to pass inert gas in aluminum alloy melt in the aluminum alloy melt. It is broken and ejected at high speed when […]

Aluminum Liquid Purification is important, because the electrolytic aluminum solution contains a large number of non-metallic inclusions and carbides, nitrides, and sulfides. When the electrolytic aluminum liquid directly enters the melting pool of the smelting furnace, it is easy to adhere to the refractory lining of the smelting furnace, and is closely integrated with the […]

Aluminium degassing machine most notable feature is the graphite stator and graphite rod/rotor structure. The graphite stator does not rotate in the molten aluminum and protects the graphite rod/rotor assembly. The graphite rod and the graphite rotor are assembled together to stir the aluminum water. The inert gas passes through the gap between the stator […]

The aluminium degassing flux is a white powder or granular flux, which is prepared by mixing various inorganic salts in a certain proportion after drying treatment. The refining agent is mainly used to remove the hydrogen and floating oxidized slag inside the liquid aluminum. So the liquid aluminum becomes purer, and it has the function […]