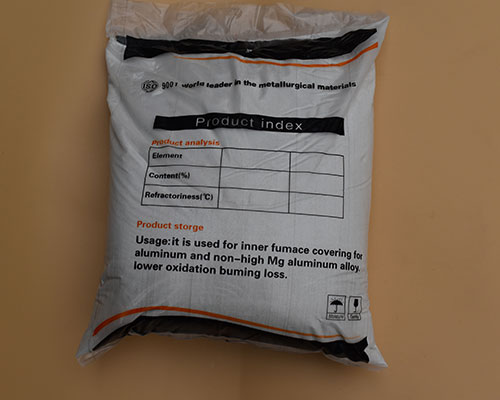

The Alu alloy flux contains adsorptive and fusible compounds, which can strongly absorb and melt oxides and aluminum slag. These foreign matters are adsorbed on the bubbles and brought to the surface of liquid aluminum with the rising of bubbles. In this way, the liquid aluminum will be purified by degassing and slag removal.

Dubai aluminum uses a specially refined dust collector, which is sprayed to the bottom of the bath by a carrier gas (nitrogen or argon). A large number of bubbles are formed at the bottom of the liquid aluminum, which floats upward from the bottom and in full contact with the melt. Through physical and chemical action, the gas and inclusion in liquid aluminum can be brought to the surface of liquid aluminum to achieve degassing and slag removal.

After a large number of applications of Adtech Alu refining flux, Dubai aluminum has proved that this refined preparation has a remarkable effect on degassing and slag removal of pure aluminum and aluminum alloy.

Adtech specializes in the R & D, production, and sales of refining agents for aluminum alloy castings. The traditional degassing and slag removal effect is used in the casting and rolling process of many series of aluminum alloy products: micron aluminum foil, printed PS substrate, canned materials, flexible packaging materials, rail transit, aerospace products, cable casting aluminum alloy, etc.

The manufacturing process of refining flux drying and mixing: drying – raw material – mixing – Packaging – finished product.

The refining agent is melted with a low eutectic point ratio, dehydrated, and melted at high temperature, and the high melting point inorganic salt is processed to produce low melting point mixed inorganic salt, which is cooled and crushed into powder. The method of drying and mixing the purified flux is to fully dry and dehydrate the inorganic salt, and add it into the components that are conducive to dehydrogenation and deslagging according to the distribution proportion of the eutectic point of the molten salt.