The aluminium cast ceramic foam filter removes impurities in molten metal, refractory waste, solid refractory alloy, and sintered ore when casting products in aluminum plants, eliminates turbulence, reduces casting porosity, and improves casting quality. Therefore, our ceramic foam filters are widely used in the aluminum casting industry to prevent defects caused by oxides, scum, gas, slag and other impurities.

The non-metallic inclusions of molten aluminum alloy in the melting and casting workshop will seriously affect the quality of castings. Usually, during the condensation process, non-metallic inclusions float to the liquid level before entering the crystallizer, which will cause white spots and pinholes on the surface of the plate and foil to increase in the subsequent rolling process, and the mechanical properties of the material will decrease, which will eventually lead to the product scrapped. Therefore, the aluminum alloy melt must be purified.

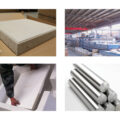

With the gradual development of aluminum industry applications, products have higher and higher technical requirements for melt processing. The production of green aluminum requires melt processing equipment to comply with environmental protection policies. Only by continuously improving aluminum refining technology can we meet the higher quality standards of users and maintain continuous competitiveness in the production of high-performance and high-quality materials.

The aluminium cast ceramic foam filter provides the best way to eliminate non-metallic inclusions, which are the main source of casting quality problems. And to help you meet the ever-increasing demand for quality.

The aluminum foundry ceramic foam filter can effectively remove the large impurities in the molten aluminum and absorb the micron-level impurity particles, thereby improving the surface quality, improving the product performance, improving the microstructure, and increasing the output. Ceramic foam filters are widely used in the production of aluminum profiles, aluminum foils and aluminum alloys. It eliminates the turbulence in the metal flow, the metal flows smoothly, and avoids splashing and collapse. At the same time, it improves fluidity, castability, processability, output and cost-effectiveness.

The 30ppi-40ppi cast filter is the most commonly used ceramic foam filter in the aluminum casting industry. Ordinary aluminum castings usually use 10-40ppi ceramic filter plates. Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.