Aluminum alloy filtration technology performs secondary purification before the aluminum alloy liquid enters the molding compound. The degassing and slag removal capabilities are very significant. This kind of filtration technology is gradually becoming mature. At present, aluminum alloy filtration technology can be successfully applied to casting production such as sand mold, metal mold casting, low pressure casting, precision casting, and lost foam casting.

Aluminum alloy filtration technology can reduce the impurities and inclusions in the melt. The quality of aluminum melt treatment will affect the product quality of the ingot, and then affect the product quality of subsequent processed materials. Therefore, aluminum melt filtration technology is an important part of the production technology of aluminum processing materials.

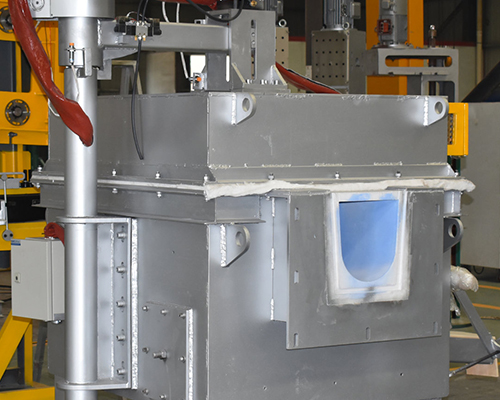

Aluminum melt filtering device is an application of this technology. The commonly used aluminum melt filter device is the CFF foam ceramic filter box. The CFF ceramic foam filter box is composed of a filter box body and a CFF filter plate. The filter box body is composed of multiple layers of refractory materials and steel structure. The refractory material in contact with the melt is generally made by one-time casting with non-stick aluminum castable. Some filter boxes are also equipped with heating devices, which are generally arranged at the top or bottom to keep the melt warm.

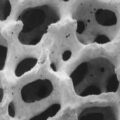

The foam ceramic filter plate is injected into the sponge plastic with a mixture of AI2O3 and phosphate, and then dried and sintered to volatilize the sponge plastic, thereby forming tortuous channels and pores in the filter plate. When filtering, the aluminum melt is blocked by the filter plate and flows along the tortuous channels and pores in the filter plate. The impurities and inclusions in the aluminum melt are in contact with the inner surface of the filter plate pores under the effects of deposition, inertia, interception, etc., and stay in the gaps, shrinkage holes, caves and other places in the filter plate, and are affected by the aluminum melt fluid axially. Under pressure, friction, surface adsorption, etc., the impurities and inclusions in the aluminum melt are firmly left in the filter plate and separated from the aluminum liquid.