The purpose of aluminum liquid purification is to remove the gas (mainly hydrogen) and solid impurities (mainly alumina) in the aluminum liquid. Purification of molten aluminum requires the use of substances that can separate aluminum oxide and drive hydrogen out of the molten metal, but do not dissolve in the molten aluminum itself. This aluminum liquid purification substance is called flux.

According to its functions, the aluminum liquid purification flux can be divided into a covering flux that prevents the oxidation and inhalation of the molten aluminum; a slag remover that promotes the separation of oxides and the molten aluminum into the scum; and a degassing flux that drives out the supersaturated hydrogen dissolved in the molten aluminum. In the smelting of aluminum-magnesium alloys, the covering flux also has the effect of preventing the evaporation of magnesium from the molten aluminum. However, in pure aluminum smelting, the covering flux is generally not used, because the oxide film on the surface of the molten pool has better isolation ability, which can prevent the aluminum liquid in the molten pool from continuing to oxidize and inhale without violent agitation.

The basic requirements for the refining flux are basically similar to the requirements for the covering agent. The difference is that as a refining agent, it emphasizes the refining properties of the flux and the separation from the melt. The refining property of the flux refers to the ability of the flux to absorb and dissolve the oxide inclusions in the molten aluminum.

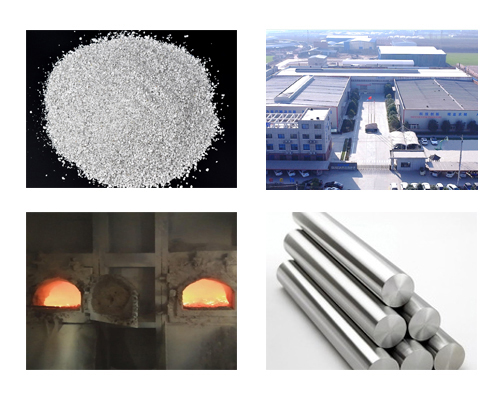

The covering flux is required to be powdery so that it can be spread and melted quickly to form a covering layer. The refining flux requires granular form to extend the refining time and make full and effective use of the flux.

When inert gas is used for air blowing and refining, it has the characteristics of convenient operation, environmental protection and safety, and low cost. While blowing in inert gas and introducing a certain amount of powdered flux, the bubble surface is surrounded by the molten flux film, which not only cuts off the contact of moisture and oxygen in the bubble with the molten aluminum, but also prevents it from forming an oxide film. Moreover, even if oxides are formed, they will be adsorbed by the flux film, thereby effectively improving the refining effect.