In the casting process of the 6061 aluminum rod, the aluminum liquid contains these various impurities, so it needs to be purified before casting. The most common aluminum rod purification method used in the industry is to use fluxes, gases, and other purification methods.

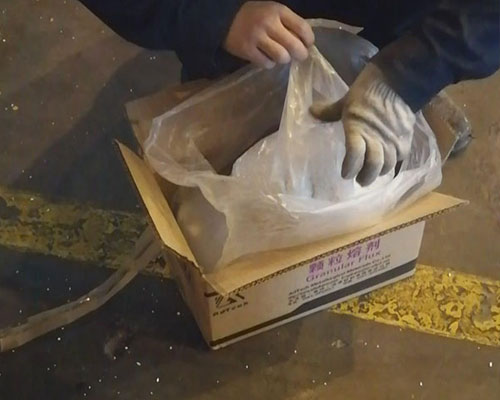

Fluxes purification method, flux purification is to use a special refining flux added to the aluminum liquid to form a large number of droplets so that the oxides in the aluminum liquid are wetted, absorbed, and dissolved by these droplets to form new droplets to the surface. After cooling, they can form floats. Slag removal. The flux for flux purification needs to choose a flux composed of salts with low melting point, low surface tension, low density, low activity, and strong adsorption capacity for oxides. When using it, you only need to put a small piece of flux into the iron cage, then insert it into the bottom of the mixing furnace and stir it back and forth to remove the iron cage after the solvation is complete, and let it stand for 5 to 10 minutes to remove the surface scum to cast. Sprinkle the granulated flux on the surface to cover it.

Gas purification method, the gas purification method is also the most common and the most important method in the 6061 aluminum rod purification method, and the gas purification method is also divided into three gas purification methods:

(1) Chlorine purification method: The chlorine purification method is to pass the chlorine into the aluminum liquid, which will produce very rich and unusually small bubbles (ALC13) fully mixed in the aluminum liquid, and ALC13 will adsorb the impurities in the aluminum liquid. On the bubbles, as the bubbles rise to the surface of the aluminum industry, the use of chlorine can also be used to pass the 6061 aluminum rod negatively and calcium, sodium, magnesium, etc. to be chlorinated to generate the corresponding chlorides to be separated. The chlorine purification method is a very effective method for purification of primary aluminum. However, because chlorine is toxic and relatively expensive, in order to avoid air pollution and production costs, it has been gradually changed to nitrogen purification.

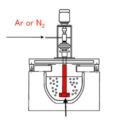

(2) The nitrogen purification method can also be called a smokeless continuous purification method. The aluminum oxide ball is used as a filtering medium to pass into the aluminum liquid, and the aluminum liquid is sent into the purification furnace through the aluminum oxide ball filter layer and is flushed by nitrogen. The non-metallic impurities and dissolved hydrogen in the aluminum liquid are removed and then continuously discharged, so that the nitrogen bubbles are evenly distributed in the aluminum liquid to be processed for purification. The most important thing is that nitrogen does not pollute the atmosphere and the purification capacity is large. It can process 200-600kg of aluminum liquid per minute. Although he can’t think of chlorine to clear the calcium, sodium, and magnesium in the aluminum liquid, it will greatly increase in the purification process. Reduce the loss of aluminum.

(3) The mixed gas purification method, as the name suggests, is to mix chlorine and nitrogen to purify the aluminum liquid, so that the aluminum rod can remove hydrogen and separate oxides on the one hand, and can also remove metal impurities in the aluminum liquid. The mixing ratio is usually 90% nitrogen + 10% chlorine or 10% chlorine + 10% carbon dioxide + 80% nitrogen. This effect is better, carbon dioxide can diffuse chlorine and nitrogen well, which can shorten the operation time.