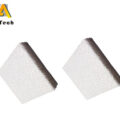

Aluminum silicate fiber plug is important for the casting process of aluminum and aluminum alloy rods. Its main function is to block aluminum liquid and control the flow of aluminum liquid in aluminum and aluminum alloy casting. AdTech tap out cone can withstand high temperature and corrosion, and has high toughness and low density. It adopts a hollow cone structure design. It is possible to reduce the waste of materials as much as possible on the premise of meeting the requirements for use, thereby reducing the waste of resources and the production and use costs. The aluminum silicate fiber plug can form a complete transition with the aluminum liquid interface to prevent the aluminum liquid from flowing out.

Manufacturing Method of Aluminum Silicate Fiber Plug

- Pour high-purity ultra-fine aluminum silicate fiber into the beating pond, add fiber softener magnesium oxide and industrial sillimanite.

- Adopt the motor water pump circulation system, stir the fiber and fiber softener together evenly, and after repeated washing several times, pump the slurry into the storage room for 20 hours.

- The aged slurry is drawn out, and add a binder. The binder is selected from one or more of silica sol, carboxymethyl cellulose, and white latex, and weighed according to the specified ratio.

- Using a conical plug forming mold, vacuum pump suction operation is used to adsorb the fiber slurry on the surface of the mold to make a plug blank.

- Place the blank on the iron frame and push it into the electric drying room for drying. The drying temperature is set at 1500-1800 ° C, and the drying time is 6-8 hours;

- Take out the fully dry plugs, wrap them according to the fixed number of large and small heads, and pack them.

After drying, the aluminum silicate fiber plug products are characterized by excellent corrosion resistance, high toughness and low density, and will not be eroded and penetrated by the aluminum solution when blocking the aluminum liquid, ensuring that the aluminum liquid is not contaminated by impurities.