Aluminum Alloy Degassing Flux is mainly used to remove hydrogen and scum in molten aluminum, and purify high temperature aluminum alloy melt. Its basic function is to remove internal inclusions and hydrogen from high temperature melt. As a result, molten aluminum becomes simpler. Some members of the aluminum concentrate are easy to decompose at high […]

AdTech degassing agent is used for removing the hydrogen, oxides, and nonmetallic inclusions. AdTech degassing refining flux utilizes unique technology to enhance the traditional degassing and deslagging effect, and this technology applies to the casting process of multi-series aluminum alloy products such as micron-sized aluminum foil, PS baseboard for printing, canning material, elastic packaging material, […]

Aluminum melt flux cleaning process can be combined with rotary gas purging. In this process, the best degassing, oxide removal and slag reception with low aluminum content are ensured. In the absence of aluminum melt flux, this rotary treatment is less effective for the removal of oxides and results in the formation of slag with […]

The slag removal ability of the Aluminum Drossing Flux is determined by the adsorption and dissolution of the oxidized inclusions in the melt by the flux and the chemical interaction between the flux and the melt. Because the oxide inclusions are not wetted by the molten aluminum, the interfacial tension between the two is very […]

The essence of Molten Aluminum Refining Agent is to use the difference of wettability between inclusions and melts when liquid flux is used to purify melt, so that inclusions move spontaneously from melt to flux. At the same time, gas diffusion and dissolution adsorption are used to remove impurities and remove hydrogen. According to the […]

The purification method of aluminum alloy can be divided into adsorption purification and non-adsorption purification. Adsorption purification refers to the direct contact between the aluminum melt and the adsorbent, so that the Aluminum Casting Foundry Flux and the solid inclusions and gas in the melt undergo physical and chemical reactions to achieve the purpose of […]

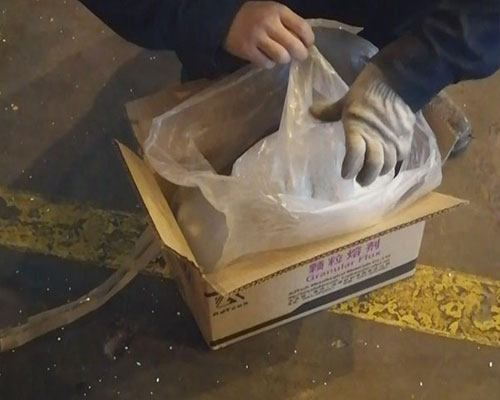

Alu Granulated Flux is used for slag removal of aluminum and aluminum alloys. Its main components are sodium chloride, potassium chloride and magnesium chloride. Chloride components account for more than 80%. With optical density, it can be well dispersed on the surface of aluminum melt, but the flux containing chlorine salt only has limited ability […]

The aluminium casting flux used in production actually has three functions of adsorption, dissolution, and combination of slag-making. The slag-removing effect is dependent on refining temperature, time, and flux properties. Refining Temperature When the aluminum drossing flux is constant, the main factor slag-removing affecting is temperature. Increasing the refining temperature is also beneficial for adsorption […]

In the smelting process of aluminum and aluminum alloys, hydrogen and oxidized inclusions are the main substances polluting the aluminum melt. Aluminum easily forms A1202 or sub-alumina (Al2O and A10) with oxygen. At the same time, it is also very easy to absorb gas (H) whose content accounts for 70-90% of the total gas in […]

Fluxes Used in Aluminum Liquid can also effectively remove the oxide film on the surface of the melt and improve the degassing effect. Fluxes used in aluminum liquid are generally composed of alkali metal and alkaline earth metal chlorides and fluorides. The main components of which are KCl, NaCl, NaF, CaF, Na3A1F6, Na2SiF6, etc. The […]

- 1

- 2