High Aluminium Launder System is one of the basic equipments for aluminum alloy casting. Its main function is to divert the aluminum liquid from the furnace to the casting machine. The working area was originally built using a flow tank for the traditional high-temperature resistant castable. In the process of use, the launder and trough […]

Molten Aluminum Trough System is the integrated launder unit manufacturer which is specialized in the development of new material and production of high-performance insulation sealing. Since 2012, our company has started to R&D overall launder, degassing unit and plate filtration unit. Supply integration services in high-precision aluminum alloy casting. Aluminum casting launder eliminates equipment and […]

Molten Metal Trough System is equipped with launder covers to prevent dangerous and expensive leaks, has gentle heating to maintain a constant molten aluminum temperature, and is highly insulated to prevent energy loss, and is fully customizable to any casting cell or casting layout. Our Launder system responds to any changes, ensuring a uniform height […]

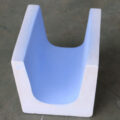

The conveying launder is the heat preservation channel for conveying molten aluminum. The casing launder is welded with steel plates, and a U-shaped trough made of thermal insulation and refractory materials is installed inside. The launder should be designed to be as short as possible, and at the same time, it is best to be […]

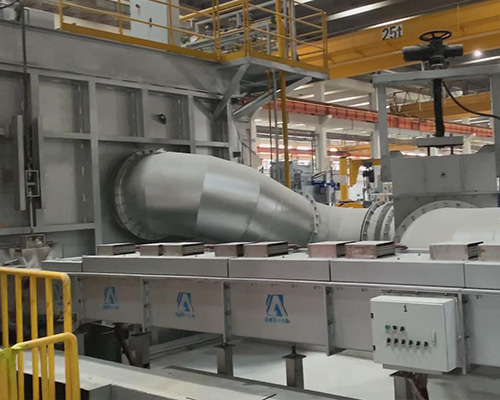

Launder System for Brazil Aluminium is mainly used for liquid Aluminium transport, used to connect liquid Aluminium in the normal transport between smelting furnace, degassing and filtration equipment and casting platform. Advanced production technology is adopted to greatly improve the scouring and erosion resistance of the casting launder liner. Launder System has effectively service life […]

تأتي المغاسل المقاومة للحرارة بأشكال وأحجام عديدة ، ويمكن أيضًا تسميتها أحواض أو عدائين أو العديد من الأسماء الصناعية الأخرى. تغطي المغاسل المقاومة للحرارة مجموعة من التركيب البسيط للغاية في الموقع إلى الأجزاء الجاهزة المخصصة للتكوينات Y أو T ومكونات التحكم في التدفق. يمثل الغسل والحوض تحديًا خاصًا للحراريات. هذا هو المكان الذي ترى فيه […]

Система с подогревом желоба транспортирует расплавленный алюминий из печи в систему дегазации и установку для литья под давлением, что является наиболее передовым методом. Желоб сводит к минимуму турбулентность и оксиды в расплавленном металле. Более того, поскольку металл плавно поступает в раздаточную печь, это исключает необходимость перевалки и использования монорельсов, вилочных погрузчиков и ковшей. Он автоматически […]

The ceramic movable trough has a long service life. Special raw materials are completely non-wetting with aluminum, and the launder liner is painted with BN coatings, which can extend the launder service life. The ceramic movable molten metal trough is mainly used for the transportation of molten aluminum and aluminum alloy. The product has the […]

The molten aluminum trough and launder have an excellent high-temperature resistant lining, and it is in direct contact with the melt. It has excellent heat preservation performance, thermal shock resistance, compressive strength, long-term erosion resistance of molten aluminum, and long service life. Aluminum and aluminum alloys are widely used metal materials in modern industry. The […]

The launder system for molten aluminum is an important part used in the aluminum and aluminum alloy casting process. It is usually installed between the melting furnace and the casting platform, and its main function is to guide the aluminum melt. The casting process of the secondary aluminum production system is to put the recycled […]