Porous Ceramic Filter Filtration can remove alumina and other nonmetallic compounds, such as lithium oxide from the molten aluminum lithium alloy. The porous ceramic filter may be a cellular structure or a foam with interconnect pores. As everyone knows, in order to remove alumina from molten aluminum or aluminum alloy, aluminum or aluminum alloy is […]

SEO

Molten metal filter filtration adopts a unique ceramic filter, forming a high average surface area network, irregular, three-dimensional, open hole structure. These ceramic foam filters are widely used in casting aluminum alloy, stainless steel, super alloy, cobalt and copper alloy, zinc and zinc alloy, iron and steel. Molten Metal Filter Filtration Benefit By reducing the […]

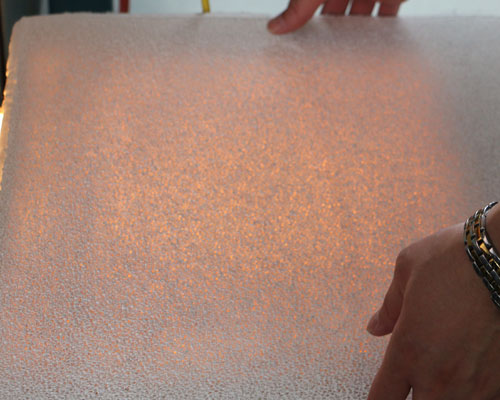

The pressure drop or alternative flow reduction caused by the Ceramic Filter for Aluminium Foundry is affected by the length of the Filters, the roughness of the filter and the effective filter area. The effect of filters on mold filling behavior has been evaluated by direct observation experiments. Direct observation is a very useful way […]

Cake filtration is the most common mechanism in which the foam ceramic foundry filters acts as a sieve and retains particles larger than its pore size on the surface of the filter. These retained particles then form a screen and capture particles smaller than the filter aperture. As the cake accumulates on the surface of […]

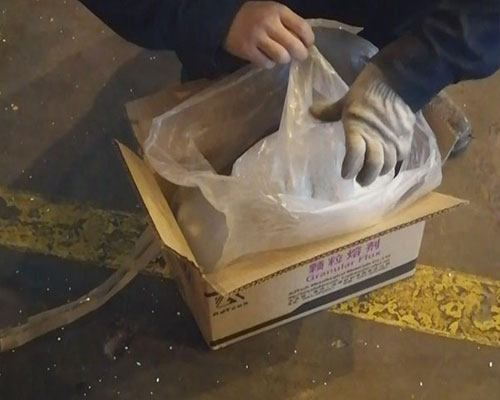

Furnace cleaning flux is used to clean the hard slagging of the furnace, furnace wall, and bottom after aluminum and aluminum alloy smelting. The accumulation on the inner wall of the refractory material of the reverberatory furnace not only reduces the life of the refractory material, but also reduces the volume of the furnace, which […]

Aluminum melt flux cleaning process can be combined with rotary gas purging. In this process, the best degassing, oxide removal and slag reception with low aluminum content are ensured. In the absence of aluminum melt flux, this rotary treatment is less effective for the removal of oxides and results in the formation of slag with […]

Rotary degassing device is suitable for gas removal treatment between furnace and casting position. Through the vertical hollow shaft and the rotor at the lower end of the shaft, the inert gas is blown into the melt, and it is distributed as tiny bubbles. Through the rotation of the impeller, the fine bubbles and the […]

Rotary Degassing Unit is used to complete degassing operation. Inert gas is introduced to produce efficient small bubbles. Short processing time and reduced gas use can save a lot of cost. The degassing treatment of the melt causes the injector immersed in the melt to rotate so that the scavenging gas (usually inert gas) is […]

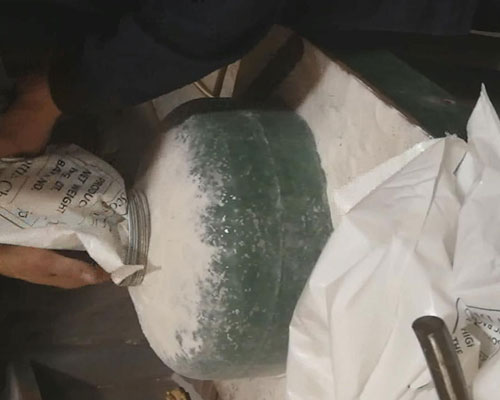

Deslagging Flux has the ability to absorb inclusions to float to the surface of the molten aluminum and form dry slag. The compound in the flux reacts with the impurities in the aluminum liquid, so that the oxide becomes more stable, and it is easy to generate high-temperature oxides with a smaller affinity for molten […]

Slag remover belongs to a processing flux for purifying aluminum alloy melt. It is composed of a variety of chlorides and fluorides. It has not only a remarkable slag removal effect, but also degassing and covering functions. Slag removal and degassing are the two central links and ultimate goals of aluminum alloy melt purification treatment, […]