The caster tip for continuous casting is generally made of a low-density ceramic material that can withstand the wear and thermal shock associated with liquid aluminum contact, such as a ceramic fiber board formed into the necessary shape. Because of the low density of these materials, they have a low thermal conductivity and can provide […]

Casting nozzles have been made of various refractory materials. The part of the nozzle in contact with the molten metal is a refractory material composed of silica, asbestos, sodium silicate and lime. Although the refractory nozzle exhibits good thermal insulation and low heat capacity, it is not very uniform in terms of chemical composition and […]

During the assembly process of the roll caster feed tip, the gasket is also permanently fixed to the top or bottom member by any means. The spacers extending through these guides are made of refractory material that is not wetted by molten aluminum alloy. Most preferably, the guide and the spacer are adapted to extend […]

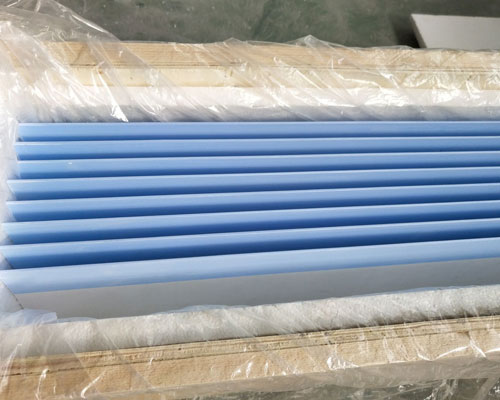

By combining a pair of slender feed nozzle components with a non-corrosive cushion, a molten metal feed nozzle for a continuous roll casting machine is made. The feed nozzle members are spaced a sufficient distance apart to allow molten metal to pass through the downstream edge to engage the surface of the continuous casting roll. […]

The filter plate has an open-pored structure, which is characterized by having a plurality of interconnected voids, so that molten metal can pass through to remove entrained solids. Such filters include solid filter plates made of sintered ceramic aggregate. A ceramic foam filter with an open-cell structure, which is characterized by a plurality of interconnected […]

Aluminum-silicon alloy is widely used in the production of casting products for aircraft parts, pistons and valve sleeves, and other internal combustion engine parts. In order to obtain suitable (high-quality) casting products, it is necessary to add a structural refinery to the casting. The alloy is melted to induce the formation of relatively small silicon […]

When the aluminum alloy melts, the molten metal refining flux is used to eliminate the hydrogen that forms the hole during the solidification of the molten aluminum alloy, and cleans the molten aluminum alloy by eliminating non-metallic inclusions that cause internal defects. The recovered scrap is melted in the molten metal by the melting process, […]

The filtration capacity (the efficiency of removing inclusions) depends mainly on the mesh roughness (number of meshes) formed in the aggregated mesh components. Therefore, in order to remove about 10-25 μ m small inclusion particles, the refractory aggregate mesh member has fine mesh, in particular, more than 2 openings per inch, more preferably 6 or […]

The molten aluminum foam ceramic filter has an open cell structure and a plurality of interconnected voids surrounded by a ceramic fiber mesh. The porous structure of the filter helps filter molten metal. The molten metal is poured into a ceramic foam filter to remove entrained solids from the molten metal. The air permeability of […]

The purification of molten metal plays an important role in improving the mechanical properties of castings. At present, the filtering device used to purify molten metal is mainly ceramic foam filter used for aluminium castings, which can effectively intercept harmful impurities in molten metal, convert molten metal from turbulent flow to laminar flow, and completely […]