Temperature control and melt purification are important for Aluminum Production Process. In aluminum casting production process, 20%~30% solid cold material is generally added for batching. First, add the aluminum ingot for remelting or the first-grade scrap of this alloy, then add the intermediate alloy, and finally inject the electrolytic aluminum liquid. The high-temperature heat of […]

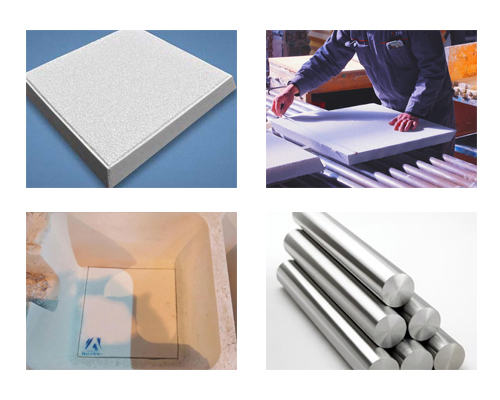

The plate filter equipment mainly filters the aluminum liquid through the ceramic foam filter. The foam ceramic filter plate is currently the most effective tool for removing the oxide inclusions in the aluminum melt. General fiber filtration can only remove large inclusions, while the foam ceramic filter plate can simultaneously filter out large inclusions and […]

In the aluminum melting and casting process, the purity of the aluminum melt is related to the metallurgical quality of the ingot, so it is very important. Nowadays, there are three main methods for filtering aluminum melt impurities, namely: CFF (ceramic foam filter) filtration, DBF (deep bed filter) filtration, and tubular filter filtration. CFF and […]

When the casting speed and cooling water volume (water pressure) both reach the normal value of casting, Aluminum Ingot Casting Process begins to enter a stable stage. At this stage, the casting speed and cooling water volume (water pressure) all reach the maximum, and the casting temperature can be 5°C to 10°C lower than the […]

Metal melt ceramic foam filter has become the most advanced filter, especially in aluminum casting operations. Various melt refining technologies have continuously improved the quality of castings. The production of high-quality aluminum products requires extensive melt processing processes, especially with the increasing focus on recycling and sustainability. Filtration is a common process to remove non-metallic […]

Many enterprises use the electrolytic aluminum liquid as much as possible to directly put it into the melting furnace of casting and rolling, which saves the energy required for the secondary remelting of remelted aluminum ingots, reduces burning loss, and realizes energy saving and emission reduction. Although the use of electrolytic aluminum liquid to directly […]

During the casting process, online aluminum melt processing is necessary. The aluminum alloy melt flows through the online degassing device and the online filtering device from the orifice of the holding furnace, and then enters the distribution plate for hot-top casting. The main points of online aluminum melt processing are as follows: (1) Add grain […]

The aluminum melt refining in furnace is carried out in two steps: The first step is pre-refining in the melting furnace. When the chemical composition and temperature of the aluminum alloy liquid in the melting furnace meet the requirements, the high-purity argon gas is used as the carrier to pass the refining agent into the […]

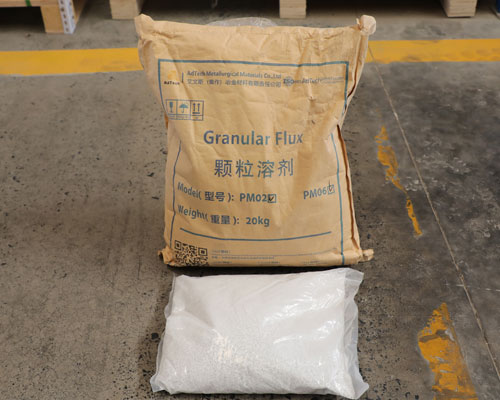

The aluminum foundry refining flux is white powder or granules with uniform particle size. Its main components are chlorine salt and fluorine salt. After proper heat treatment and sieving of the foundry flux, the nitrogen in the refining tank can evenly enter the lower layer of the molten aluminum through physical and chemical changes. The […]

How to Use Aluminum Alloy Flux? 1. In the range of refining temperature, a fixed amount of casting aluminum refining agent is put into the dust collector storage tank. 2. Blow-in nitrogen and turn on the switch under the refining tank. 3. When there is aluminum refining agent in the iron pipe, insert the iron […]