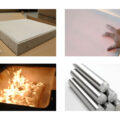

Metal melt ceramic foam filter has become the most advanced filter, especially in aluminum casting operations.

Various melt refining technologies have continuously improved the quality of castings. The production of high-quality aluminum products requires extensive melt processing processes, especially with the increasing focus on recycling and sustainability. Filtration is a common process to remove non-metallic inclusions in aluminum, and metal melt ceramic foam filters (CFF) are commonly used as filter media.

The wetting behavior between liquid aluminum and a substrate made of industrial Al2O3 and SiC-based ceramic foam filters (CFF) was studied. The same CFF filter was also tested in a factory-scale filtration experiment. The results of the wetting experiment show that the SiC-based filter material has a better wetting effect on liquid aluminum than the Al2O3 -based filter material. This indicates that the improved wetting of aluminum on the filter material is an advantage of molten metal penetrating the filter during pouring. In addition, due to the better contact between the filter and the metal, the better wetting of the aluminum filter may increase the removal efficiency of inclusions during the filtration process. Unwetted inclusions are easier to remove.

In aluminum foundries, alumina ceramic foam filters are usually used to capture non-metallic inclusions. It is well documented that solid inclusions are captured and retained in the large pores of the filter at the metal-refractory interface. However, liquid inclusions seem to be captured and retained by two mechanisms: one is in the microporous structure of the filter mesh, and the other is as a liquid film at the metal-filter macroporous interface.

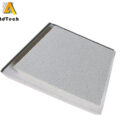

Metal Melt Ceramic Foam Filter Features

- A homogeneous pore structure

- High surface strength

- Temperature resistant up to 1100°C

- Excellent resistance against chemicals used in foundries

- Machined to tight dimensional tolerances

- Excellent strength and thermal properties

- Resistant to molten aluminium attack

- Available in various sizes and grades

- Reduced scrap

- Better surface finish of castings

- Increased metal quality