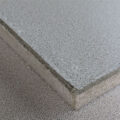

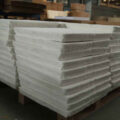

The ceramic filter for metal casting is the most effective way to remove inclusions in aluminum melt. As for the filtration of metal filter screens and fiber cloths, only large inclusions in the aluminum alloy melt can be removed, but inclusions below micrometers cannot be removed. The metal filter screen will also pollute the aluminum alloy.

The ceramic foam filter for metal casting can filter out fine inclusions and significantly improve the mechanical properties and appearance quality of the castings. It is the first choice for melting and foundry.

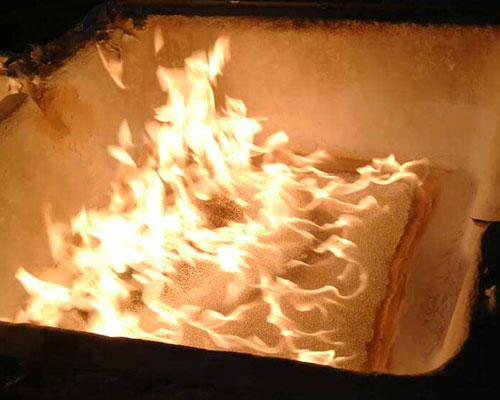

In the melting, refining, and formation of metals, especially in the casting of molten metal, it is desirable to separate inclusions from the molten metal. If these inclusions are not removed from the molten state of the metal, the performance of the final solidified metal body (the final product of the casting operation) may be reduced.

Part of the inclusions in aluminum alloy come directly from the charge, most of which are formed during the melting and casting process, mainly oxide inclusions.

All the inclusions before casting are called primary oxidation inclusions, which can be divided into two categories according to their size: one is the large inclusions with uneven distribution in the macrostructure, which makes the alloy structure discontinuous and reduces the compactness of the casting. It becomes the source of corrosion and the source of cracks, thereby greatly reducing the strength and plasticity of the alloy. The other is small scattered inclusions, which cannot be completely removed after refining, which will increase the viscosity of the metal melt and reduce the feeding capacity of the molten aluminum during the solidification process.

The secondary oxidation inclusions are mainly formed during the casting process. During the casting process, the molten aluminum contacts the air, and the oxygen reacts with the aluminum to form oxide inclusions. During the smelting process, the aluminum alloy comes into contact with various components in the furnace gas, forming compounds such as Al2O3. The Al2O3 in the molten aluminum will increase the hydrogen content in the molten aluminum alloy. Therefore, the content of Al2O3 in molten aluminum has a great influence on the formation of pores in aluminum castings.

In addition to using ceramic foam filter plates to remove impurities, it is also necessary to prevent re-contamination of the filtered clean aluminum liquid.