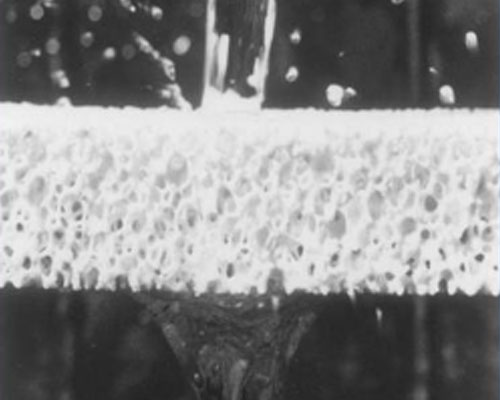

Metal Filtering with CFF is a supplement to metal treatment within the furnace, such as fluxing and degassing or inline filtration. Ceramic foam filters offer a simple, reliable, and cost-effective method to remove inclusions. With the demand for high quality aluminium products increasing, filtering with CFF has proved an optimum method for improving metal quality. […]

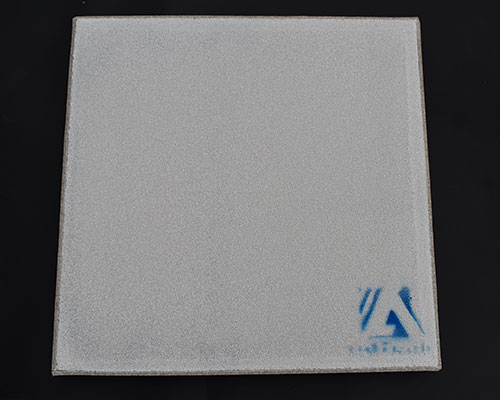

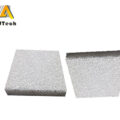

Our Foam Ceramic Filter Materials are made of the basic raw material Aluminium Oxide. AdTech alumina foam ceramic filter can effectively remove large-size inclusions in molten aluminum and can effectively adsorb small-size inclusions. They are manufactured with porosities varying from 10 to 60 pores per inch (PPI). Also, combo sets are made in 20-30 PPI […]

The amount of Aluminum Alloy Casting Flux added to aluminum alloy casting should be determined according to the weight of liquid aluminum, because too much or too little will affect the performance of aluminum alloy, so it must be calculated before adding. When operating the refining agent, the operator should control the refining flow freely […]

Alu Foundry Fluxes are white powder or particle with uniform particle. It is made by drying a variety of inorganic salts and mixing them in a certain proportion. It is mainly used to remove hydrogen and floating oxide slag from molten aluminum. Alu Foundry Fluxes must meet the following conditions: 1. The melting point should be […]

Aluminum Alloy Degassing Flux is mainly used to remove hydrogen and scum in molten aluminum, and purify high temperature aluminum alloy melt. Its basic function is to remove internal inclusions and hydrogen from high temperature melt. As a result, molten aluminum becomes simpler. Some members of the aluminum concentrate are easy to decompose at high […]

Aluminum Smelter Flux is a powdery particle that is in full contact with molten metal. The gas and inclusions in the molten aluminum are brought to the surface of the molten aluminum through physical and chemical effects, and at the same time achieve the purpose of degassing and slag removal, and after a large number […]

Aluminum Alloy Casting Fluxes are used in a variety of aluminum alloy melts, and can be used for pure aluminum smelting, refining, and slagging. When using, just sprinkle the refining agent on the surface, then quickly dissolve it in the aluminum liquid, and then fully stir it. If a jet is used, it is best […]

Aluminum foundries fluxes can reduce alloy waste, control slag formation and remove impurities in alloys, which would otherwise affect quality. The formation of alumina and the presence of non-metallic inclusions seriously affect the aluminum casting process and must be managed to achieve the highest quality castings. Aluminum Foundries Fluxes can prevent excessive oxide formation, remove […]

The method of making granulated flux in molten aluminum and its alloy is to mix the salt mixture fully, then add ingredients to melt it, pour the molten liquid into a suitable furnace, grind it to room temperature after cooling, and sieve it into various sizes. Adtech is committed to the research, development, production, and […]

Granular Fluxes can reduce emissions by up to 85% without significantly reducing performance, as they allow less flux to be used and make it work in a different way. It has been found that the form of flux has a very important influence on the type and quantity of emissions. In an increasingly environmentally conscious […]