Advanced metal melt filtering devices are used in the melting and casting workshops of aluminum processing plants, mainly including CFF filtering devices, deep bed filtering devices, and tubular filtering devices. Ceramic foam filter filtration and deep bed filtration belong to internal filtration, while tubular filtration belongs to the double capture of impurities on the surface and inside.

Impurities in aluminum alloy melt contain more or less gas, various non-metallic inclusions, and other harmful metals. The presence of these impurities will directly affect the quality of aluminum alloy, causing ingots such as porosity, pores, slag inclusions, etc. Defects in turn have adverse effects on the mechanical properties, processing properties, corrosion resistance, surface treatment properties and product appearance of downstream processed products. In order to overcome the above-mentioned adverse effects, melt purification in aluminum alloy casting production becomes extremely important.

At present, ceramic foam filter filtration purification is the most effective method to remove non-metallic inclusions in molten aluminum and aluminum alloys. Without the guarantee of a suitable melt treatment process, the material cannot fully play its role.

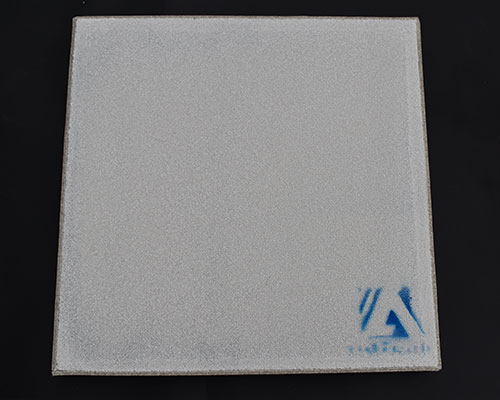

Since the first successful research of ceramic foam filter for aluminum alloy in the 1970s, ceramic foam filter technology has developed rapidly, and is currently the most widely used in aluminum processing plants. The ceramic foam filter is installed in advanced filtering devices, which can reach a better effect.

Advanced metal melt filtering devices are becoming more and more common because people have higher and higher requirements for the quality of aluminum products. The ceramic filter for casting can not only effectively remove a large number of oxide inclusions in molten aluminum, but also filter out a few microns of small inclusions which can not be achieved by traditional technology.

AdTech has good effects on foreign ceramic foam filters. The filtration level (pore size) ranges from 20PPI to 80ppi, but 30ppi 50ppi is the most commonly used. The layout of the ceramic foam filter includes single-layer filtration and double-layer filtration.