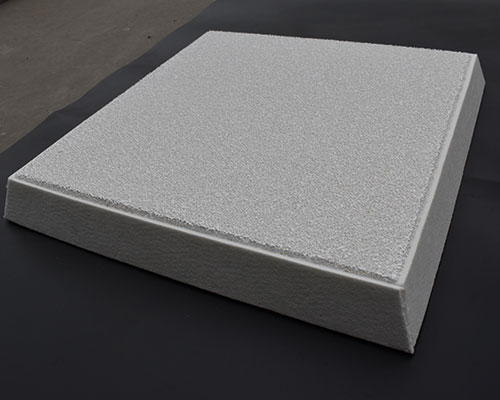

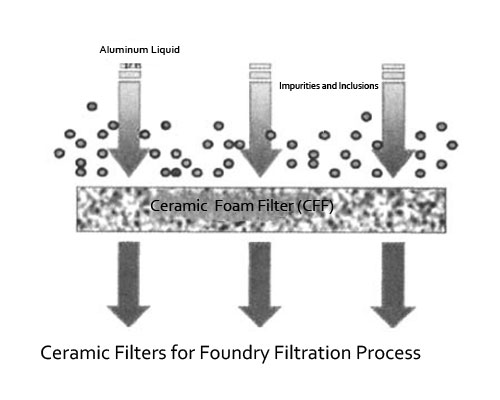

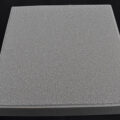

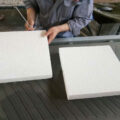

Ceramic Filter for aluminum rod foundries can filter solid slag, such as metal oxides in molten metal, thereby improving the quality and output of aluminum alloys. Therefore, the use of ceramic foam filters has promoted technological progress in the foundry industry. The ceramic porous foam filter is an open-pore mesh with a sponge-like structure for […]

How to select molten metal filters? You need to understand which filter material is suitable for your metal casting and the characteristics of the filter. Foam ceramic is an ideal form of structure. The pore size and number of pores of this structure determine the resistance of the metal liquid through the filter. When non-metallic […]

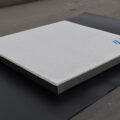

The industry in the world continuously puts forward new requirements for the quality of high-tech products such as can blanks and PS plate aluminum substrates. Ceramic foam filters are required in aluminum processing and production, which remove non-metallic inclusions from molten aluminum and its alloys. Ceramic foam filters for cast alloys are the most effective […]

Most aluminum smelting furnaces or holding furnaces in the aluminum casting industry are equipped with molten aluminum outlets, which are blocked and sealed with ceramic fiber refractory plugs. Ceramic fiber refractory plugs are also called heat preservation plugs, heat preservation cones, tap out cones, vacuum formed shapes. Our tap out cone selects ceramic fiber to […]

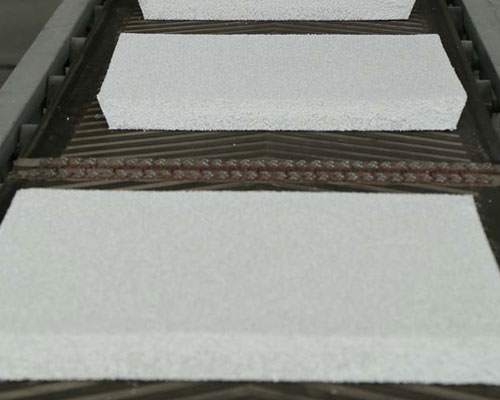

The CFF Molten Metal Filter is a phosphorus-free high-aluminum-based product, which is characterized by high porosity, good mechanical and chemical stability, and excellent heat resistance and corrosion resistance to molten aluminum. The laminar flow process provides laminar flow for filtering molten aluminum. During processing, it is processed to strict dimensional tolerances. The combination of physical […]

Filtration of molten metals with ceramic foam filters is a proven method in order to remove the inclusions. AdTech provides a high-temperature resistant foam filter that does not contaminate the melt and does not result in degradation of desirable characteristics in the final metal product. Molten metal, particularly molten aluminum, in practice generally contains entrained […]

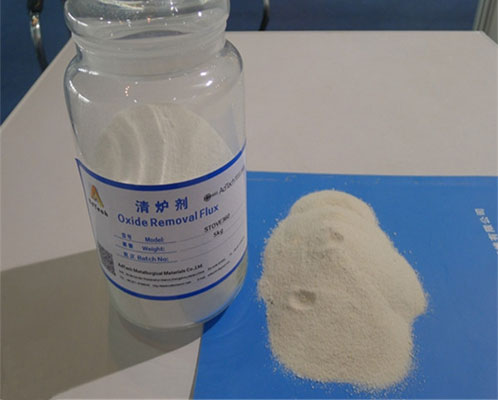

AdTech slag removal flux is white with slightly gray powdery fine particles. Slag removal flux helps to achieve aluminum alloy continuous casting and improves the quality and output, prolongs the furnace service life, reduces manual labor, applies to multi-series aluminum alloy casting in the furnace. The main ingredients are chloride and villiaumite, together with other […]

AdTech’s online degassing system uses this flotation slag removal method for degassing and deslagging. Online degassing unit shall be installed between furnace and casting equipment. It is used for hydrogen (H) and slags removal from molten aluminum. Flotation slag removal is the use of a certain physicochemical interaction between flux or inert gas and oxides, […]

Aluminum Melting Fluxes are usually added during the melting, holding or degassing of aluminium to furnaces, crucibles, ladles, or other aluminium vessels. Flux raw-material quality, addition method and product form can all affect efficiency. A flux recipe varies depending on its purpose and other process variables, such as alloy and temperature. The amount of aluminum […]

Degassing with inert gas can remove the hydrogen and inclusion in molten aluminum. Referring to the inert gases, what is contemplated is that a non-reactive gas, preferably along with a reactive chlorinaceous or other suitable halogen gas, be bubbled through the molten aluminum in the online degassing chamber. The chlorinaceous gas where employed may be […]