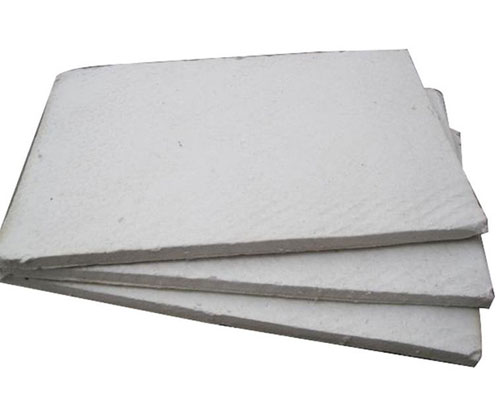

Ceramic fiber board is made by wet vacuum forming process. The strength of Ceramic Fiber Board is higher than that of fiber blanket and vacuum forming felt. It is suitable for the high temperature field with steel strength requirements. Therefore, it has been widely used in machinery, metallurgy, chemical industry, petroleum, ceramics, glass, electronics and other industries.

Ceramic Fiber Board

The main components of ceramic fiber board are Al2O3, SiO2, ZrO2, CrO2 and so on. It is a kind of light-weight refractories with the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, small specific heat and mechanical vibration resistance. It is often called the third generation refractory. Compared with traditional heavy-weight refractories and amorphous refractories, ceramic fibers not only have the excellent thermal insulation properties of general low thermal conductivity materials, but also have long-term excellent heat resistance at high temperatures.

Ceramic Fiber Board Features

- High compressive strength and long service life;

- Low heat capacity and low thermal conductivity;

- Non brittle material with good toughness;

- Accurate size and good flatness;

- Easy cutting and installation, convenient construction;

- Excellent wind erosion resistance;

- Continuous production, uniform fiber distribution and stable performance;

- Excellent sound absorption and noise reduction performance.

Ceramic Fiber Application

Iron and steel industry: expansion joint, lining insulation, heat insulation sheet and mold insulation; non-ferrous metal industry: backing insulation material, tundish and runner cover, used for pouring copper and copper alloy; ceramic industry: light kiln car structure and furnace hot surface lining, furnace temperature zone separation and fire-retardant materials; glass industry: molten pool is lined with heat insulation, burner block; furnace building: hot surface refractory material Materials (instead of fiber blanket), lining and expansion joint of heavy refractory; light industry: lining of combustion chamber of industrial and domestic boilers; petrochemical industry: lining of heating surface of high-temperature heating furnace; building material industry: thermal insulation of cement rotary kiln and other equipment.