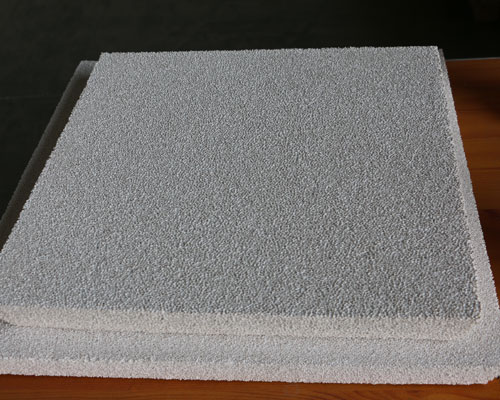

Ceramic Foam Filter MOZAL Aluminum can effectively block the slag in molten metal. When the molten metal passes through the ceramic foam filter with a complex structure, the filter medium filters out the inclusions larger than the pore size of the filter surface through mechanical separation, and makes them precipitate at the filter.

As the accumulation of inclusions on the surface of the foam ceramic filter increases, a layer of “filter cake” will gradually be formed, which further narrows the flow channel of the molten metal. Therefore, the surface of the new filter media can filter out finer inclusions. At the same time, the inside of the medium also has a filtering effect. Among the many small holes penetrating the ceramic body are possible positions for intercepting inclusions.

When the molten metal flows through the foam ceramic body, it is divided into many small streams, which increases the contact area and contact probability of the inclusions in the molten metal and the filter medium. Because the surface of the filter is extremely small uneven surface, it has electrostatic adsorption and adhesion interception effect on inclusions.

When the molten metal flows through the ceramic foam filter MOZAL Aluminum, it is divided into many small units of stream, the diameter of which is small, so that the liquid flow tends to move in a laminar flow. When the molten metal is in a laminar flow state, since the density of the molten metal is much greater than the density of the inclusions, the inclusions have sufficient time to float up and be removed.

Mozambique is a country in southern Africa. MOZAL Aluminum Corporation is the country’s largest industrial employer and has made significant contributions to the local economy. The aluminum plant is located only 20 kilometers west of Maputo, the capital of Mozambique.

The MOZAL aluminum smelter is the country’s largest private investment and the first large-scale foreign direct investment of US$2 billion, helping Mozambique rebuild after a period of turmoil.

The MOZAL aluminum smelter initially had an annual output of 250,000 tons, and was subsequently expanded from 2003 to 2004. It is now the largest aluminum producer in Mozambique and the second largest aluminum producer in Africa, with an annual output of approximately 580,000 tons. It accounts for 30% of Mozambique’s official exports and also consumes 45% of Mozambique’s electricity.

MOZAL has also begun to supply Mozambique’s first downstream aluminum company. The development of this downstream industry will promote the development of the local economy.