Grouting method of ceramic filter plate, manual glue spraying process, grouting sequence

3.1 Grouting method

3.1.1 Manual guniting process

Manual spraying is the pressure generated by the air compressor (0.5~1. OMPa)

Force, spray the slurry from the spray gun, and spray it on the surface of the green body under the control of the worker,

Spray the other side after the surface is dry. The advantages are less investment, less slurry waste, and spraying

The amount of coating shall be controlled flexibly. Disadvantages are high labor demand, low work efficiency, and slurry

Uneven adhesion, etc.

3.1.2 Automatic guniting process of ceramic filter plate

The automatic guniting process is derived from the glazing process of building Et ceramics

The slurry is sprayed on the green body surface of the drive belt or chain through the nozzle

After that, it will be dried by subsequent short hot air or infrared ray. After turning over, spray the other side, and then dry to complete the automatic spraying process. The advantages of automatic spraying are high efficiency

The green body is sprayed evenly. The disadvantages are large initial investment, large slurry waste

Frequent replacement of nozzle in later stage.

3.2 Grouting sequence of porous ceramic filter

3.2.1 Grouting after sizing

Spraying after sizing belongs to wet billet spraying. It saves the next drying process,

The green body has a general adsorption effect on the slurry. But for products with large size and thin thickness

Product. It is also suitable for spraying after sizing to prevent damage to the green body after drying

Injury. However, its disadvantage is that only one side can be sprayed, which is generally required for spraying and filtering metal melt

The front of. Considering the shotcreting effect, the shotcreting method after sizing is not very common.

3.2.2 Grouting after drying

The dry spray belongs the dry spray, which is suitable for double-sided spray, and

The slurry can be adjusted to the maximum consistency to improve the surface of the billet to the greatest extent

noodles. This is a commonly used shotcreting method in foam ceramic production. Spraying after drying

Its disadvantages are a large amount of labor, damage to the green body, easy-to-produce slag, etc.

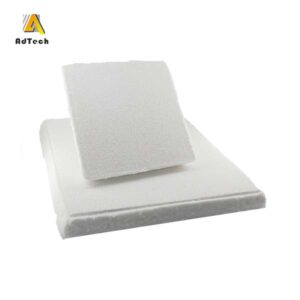

ceramic filter plate