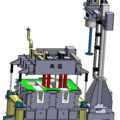

Dual Rotor Degasser is designed for online degassing liquid aluminum with high velocity, high gas content, and high inclusions. It has two independently controllable steering rotors that rotate in opposite directions to provide more powerful agitation. Good thermal insulation design can provide 24 hours of online uninterrupted degassing.

Liquid aluminum is stirred by a controlled rotating graphite shaft and a rotor, through which the measured inert gas is pressed into the liquid aluminum and broken into small bubbles to make it evenly dispersed. Due to the high partial pressure of hydrogen in liquid aluminum, hydrogen in liquid aluminum continuously diffuses into bubbles. Some non-metallic inclusions in liquid aluminum adsorb on the surface of bubbles and attach to them without hydrogen and some non-metallic inclusions.

A dual rotor degassing machine is used as an online degassing refining machine for liquid aluminum. The degassing medium is recommended to use nitrogen or argon gas with purity of 99.996% or more. The device is equipped with a gas under-pressure alarm function, when the inert gas is removed, the air source pressure drops to the limit pressure, the alarm can automatically alarm through the warning light, prompt the operator to replace the air source in time, to avoid the lack of air caused by aluminum liquid unqualified equipment double rotor. When the equipment is used as online degassing equipment, please prepare a spare air source in advance for timely replacement in case of under pressure.

Features of Dual Rotor Degasser

1. The reverse rotation of the two rotors can stir the metal melt more strongly and more evenly, improve the stronger degassing efficiency, and provide timely degassing for more liquid aluminum.

2. Easy installation and positioning of the equipment. After placement, in addition, to replacing the worn parts, basically do not need to move!

3. Two rotors can control the speed and gas flow independently.

4. simple control, button operation, degassing time can be set (0.01 seconds to 999 hours adjustable or not limited), automatic/manual control mode, generally online automatic control.

5. When the degassing time is set, the rotor will stop automatically and the air supply will be closed automatically. The flashing light reminds the operator of high safety. They are used for online degassing, and continuous operation.

6. Adopt nitrogen or argon gas as degassing medium, the advanced degassing principle significantly shorten degassing time, improve efficiency, reduce refining cost, causes no pollution to the environment, and significantly improves the working environment.

7. Inert gas flow is controllable, the best setting can be carried out, can greatly reduce the waste caused by bubbles and inclusions, greatly improve the yield, and improve the mechanical properties of the casting.

8. Provide stable, repeatable degassing effect, without affecting the production process for customers to achieve efficient production.

9. The bottom of the equipment is equipped with an insulation layer, has excellent insulation performance, and can prevent the high temperature of liquid aluminum equipment deformation.

10. Set the emergency stop button, and switch on and off the machine is simple and safe, with a firm structure, simple maintenance, and low maintenance requirements.