Purifying molten aluminum outside the furnace through ceramic foam filter plates is an effective way to improve the cleanliness of molten aluminum. The ceramic foam filtration process can effectively remove various inclusions in the aluminum liquid with a fineness of micrometers, reduce the influence of inclusions on the quality of cast-rolled billets, and provide a basic guarantee for obtaining high-quality cast-rolled billets.

To obtain high-quality ultra-thin double-zero aluminum foil products with a small number of pinholes and a high yield rate, the basic quality of the aluminum foil blanks must be strictly controlled. The combined purification treatment of aluminum melt is a key process in the production of aluminum foil blanks, and is the prerequisite and guarantee for processing high-quality double-zero aluminum foil.

Influence of Liquid Aluminum Filtration Technology

The molten aluminum refined by high-purity nitrogen in the holding furnace is further purified outside the furnace using an online degassing device, and then filtered and purified outside the ceramic plate furnace to enter the casting and rolling mill to produce cast-rolling billets.

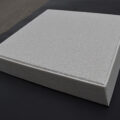

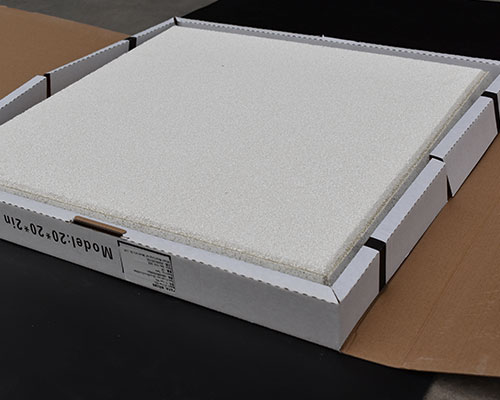

The ceramic foam filter purifying molten aluminum method used is a two-stage filter box, which is a foam ceramic two-stage filter plate with 30PPi mesh and 50PPi mesh. The aluminum liquid needs to be filtered through one stage before flowing into the front box.

The ceramic foam filter plate can effectively block the metal, non-metallic inclusions and bubbles in the aluminum melt, play a role in purifying the aluminum melt, and provide a basic guarantee for obtaining high-quality cast-rolled blanks.

As the filtering volume of the aluminum liquid increases, the pores of the filter plate will be blocked by metal and non-metallic inclusions, which will affect the cleanliness of the aluminum melt after filtration, so the filter plate needs to be replaced in time. However, replacing the filter plate too frequently will affect normal production, reduce production efficiency, and increase production costs.