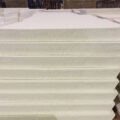

Molten Metal Filtration Australia is a new type of industrial ceramic product with low bulk density (0.25-0.65) g/cm3, high porosity (60-90%), and three-dimensional network framework. Ceramic foam filter has the characteristics of high temperature resistance, chemical corrosion resistance, interpenetration, large specific surface area and so on. Ceramic foam filter is widely used in metal melt […]

Tag Archives: Ceramic Foam Filter

Foam ceramic filter has been applied in New Zealand Aluminum production, bringing a qualitative leap in the filtration of molten metal. Foam ceramic is a kind of porous material, which has the characteristics of a three-dimensional network structure and high porosity. Due to the special structure of foam ceramics, it has the advantages of low […]

After long-term use of filter method in the Canadian aluminum casting foundry, it is proved that the ceramic foam filter plate is an effective tool for removing the oxide inclusions in the melts. General fiber filtration can only remove large inclusions, while the foam ceramic filter plate can simultaneously filter out large inclusions and small […]

Recycled aluminum alloy contains more metal and non-metal impurities and must be further refined. Impurities refining methods include ceramic foam filter filtration, gas refining, flux refining, vacuum refining, and oxidation refining. The first four methods are used to remove non-metal impurities, and the latter method is used to remove metal impurities. When the regenerated aluminum […]

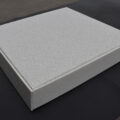

After placing the ceramic foam filter in the filter system, the filter produces a comprehensive resistance to the liquid casting alloy. This resistance mainly includes: Thermal resistance: The resistance caused by the temperature difference between the high-temperature molten metal and the filter. Force resistance: At the entrance of the filter, a large stream of molten […]

The filtration process of molten aluminum is very important. It is the last step before casting and determines the quality of the casting. In order for the metal melt to pass through the filter plate, the surface tension of the oxide film on the surface of the melt must be overcome, and there must be […]

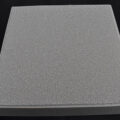

The selection of the ceramic foam filter plate should be based on the quality of the impurities in the aluminum melt, the flow rate of the melt transfer and the quality requirements of the cast aluminum products. Aluminum melt contains a lot of impurities, and the quality requirements of cast products are general. You can […]

In the production of castings, the use of foam ceramic filter metal liquid filtration technology, through mechanical interception, rectification scum and deep adsorption three filtration purification mechanisms, can effectively reduce or eliminate non-metallic inclusions, purify the liquid alloy. Thereby, foam ceramic filter metal liquid filtration improves the genuine rate and productivity of the alloy improve […]

The alumina ceramic foam filter is suitable for the filtration and purification of aluminum and aluminum alloys. It is composed of alumina, silica, talc, and kaolin to form a ceramic powder, and then adds polyvinyl alcohol, silica sol, and water to prepare a slurry. The polyurethane foam is used as the carrier, impregnated with the […]

Ceramic Foam Filters (CFF) for metal filtration have been used commercially in the foundry industry for more than forty years, are used to produce high-quality aluminum castings for applications such as the aerospace industry. In recent years, for the non-ferrous metal industry, ceramic foam filters for metal filtration have become more and more important in […]