For the technical transformation project of the 16-ton melting and casting production line of Northwest Aluminum Co., Ltd., our company designed an online degassing unit, plate filtration, deep bed filter, and online heating launder system for the northwest aluminum production line. From design liaison, design review, production and production, inspection and acceptance, on-site installation and […]

Aluminum processing enterprises production learning and exchange On May 15, 2023, a group of material R&D personnel and design process personnel went to a large aluminum processing enterprise to visit, study, and exchange technology. First, visit the feeding and melting operation process of the aluminum smelting furnace. […]

The molten metal filtering device can prevent the molten metal from solidifying and clogging due to the oxide film entering the surface of the molten metal or the temperature drop of the filter medium itself. The molten metal filter medium is made of porous ceramic material in the shape of a flat plate. This filter […]

Using a 20 PPI ceramic foam filter to filter and purify A356 alloy, by observing the changes in the tensile properties and elongation of the alloy before and after purification, the following conclusions can be drawn: The filtration and purification of the 20ppi ceramic foam filter can improve the tensile strength and elongation of A356 […]

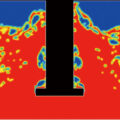

After using the ceramic foam filter for metal casting, the rectifying effect of the ceramic foam filter can be fully demonstrated. The molten metal flowing through the ceramic foam filter has a trickle and converges into the mainstream of laminar flow. The laminar flow state of molten metal fills smoothly, avoiding the secondary oxidation and […]

Foam ceramic filter board has advantages: high dimensional accuracy, high mechanical strength, stable chemical composition, corrosion resistance to liquid aluminum and its alloys, no phosphorus and environmental friendliness, purifying aluminum liquid, improving aluminum quality, reducing defects, reducing defective rate, reducing cost, increasing production efficiency, and using simple and flexible size from 40mm to 600mm to […]