Pollution problem after refining gas, hydrogen degassing discharge Due to the increasing requirements for the purification of aluminum melts in many production plants, In particular, to effectively remove alkali metals from aluminum melts, use inert Mixed refining of hydrogen degassing and chlorine in the production process will have a certain amount of exhaust hydrogen degassing […]

The presence of gas (usually hydrogen) and other particles in gravity or sand castings can cause bubbles, which can severely impair the appearance and performance (overall strength and density) of the finished product. This makes effective metal degassing critical to the quality of the casting process. Traditionally, graphite is the most widely used material for […]

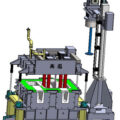

The molten aluminum degassing equipment adopts compact furnace design. In the degassing box, a rotating nozzle is used to degass the molten aluminum, and convection is formed in the box so that small bubbles can completely diffuse into the molten aluminum. At the same time, the sealing design is adopted to prevent the secondary pollution […]

Degassing with Nitrogen has been gradually eliminated in the modern aluminum industry, fluxes are generally used together with nitrogen. Use active gas chlorine as a purifying agent (chlorination method). In the chlorination method, when the chlorine gas is passed into the aluminum liquid, a lot of abnormally small bubbles are generated, which are fully mixed […]

Rotary Degassing Unit is used to complete degassing operation. Inert gas is introduced to produce efficient small bubbles. Short processing time and reduced gas use can save a lot of cost. The degassing treatment of the melt causes the injector immersed in the melt to rotate so that the scavenging gas (usually inert gas) is […]

Rotary degassing equipment is an advanced melt purification method. The purification effect is good and does not pollute the environment. The purified melt can enter the casting machine or rolling mill directly without secondary pollution, which improves the production efficiency. The purity of molten aluminum directly affects the processing quality of aluminum, so crude aluminum is […]

Degassing Aluminum with Nitrogen: Nitrogen enters the bottom of the aluminum liquid through a certain process device. The nitrogen floats up from the bottom of the aluminum liquid in the form of bubbles. Due to the hydrogen partial pressure difference at the contact interface between the bubble and the molten aluminum, the partial pressure of […]

After the adjustment of the molten metal composition is completed, the next step is the refining process of molten aluminum. The purpose of aluminum alloy refining is to obtain high cleanliness and low gas content alloy liquid after taking degassing and impurity removal measures. There are several methods for refining: Add chloride (ZnCl2, MnCl2, AlCl3, […]