Aluminum Water Filter has corrosion resistance, high temperature resistance, high mechanical strength, no harmful substances dissolved, no secondary pollution, no deformation of micropores under the action of fluid pressure, easy cleaning and regeneration, and long service life.

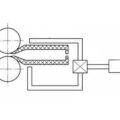

The aluminum water filter is composed of many uniform and countless micropores. When the molten metal passes through these tiny pores, suspended matter, colloidal particles, and macromolecular organic matter are trapped on the surface of the Ceramic Foam Filter, and the fluid passes through the microporous channel to produce various physical effects, achieving mechanical filtration purification or diffusion, fluidization and other effects.

According to the different purity, aluminum can be divided into the following three categories.

1) Primary aluminum. Usually refers to aluminum produced in industrial electrolytic cells by molten salt electrolysis, and its purity is generally 99.5-99.8%. This is a bulk industrial product and does not include formulated alloys.

2) Refined aluminum. Generally from three-layer liquid refining electrolyzers. In the refining tank, the alloy composed of primary aluminum and copper is used as the anode, and the cryolite-barium chloride is used as the electrolyte. The purity of the refined aluminum precipitated on the cathode is usually above 99.99%.

3) High-purity aluminum. It is mainly produced by the regional smelting method. Refined aluminum is used as raw material to obtain high-purity aluminum with impurity mass fraction not exceeding 1×10-6. High-purity aluminum can also be prepared by a combination of electrolysis of organoaluminum compounds and zone smelting.

Refined aluminum has many excellent properties compared to primary aluminum. With the increase of purity, the conductivity, ductility, reflectivity and corrosion resistance of aluminum are enhanced, which are mainly related to the grain growth of aluminum. Among them, the most valuable is its corrosion resistance. The corrosion resistance of refined aluminum is about 9 times that of primary aluminum. The higher the purity of aluminum, the denser the surface oxide film, the stronger the bond with the internal aluminum atoms, and the better the corrosion resistance.

Aluminum is a material with very low magnetic permeability and has good electromagnetic properties in alternating magnetic fields. The higher the purity, the smaller its magnetic permeability and the better the low temperature conductivity. Therefore, refined aluminum and high-purity aluminum have special uses in the fields of low-temperature electrical technology, low-temperature electromagnetic components, and electronics. The main uses of refined aluminum are in some high-tech fields and scientific research fields, mainly for the production of refined aluminum foil, the preparation of bright aluminum alloys, special aluminum alloys, and drawing and spraying wires, among which the electronics industry is the most widely used.