The molten metal filter media is used to filter molten aluminum. Reticulated foam filters using alumina aggregate particles in the binder phase are generally used to filter aluminum and aluminum alloys. Generally, inclusions, especially non-metallic inclusions, are mixed into molten aluminum. If such molten metal is rolled after casting or the like and made into […]

SEO

The molten aluminum filter material has numerous micropores uniformly distributed in the network state, and the pore size is slender and curved, and has good permeability. It has the characteristics of a capillary tube, so the solid particles form an arch bridge at the diameter of the micropore, which has little effect on the filtration […]

Ceramic foam filter is a very good product, which is widely used in molten aluminum filtration in aluminum smelting and casting process to prevent particulate impurities in molten aluminum from entering the casting billet and affecting the quality of aluminum processed products. According to the quality requirements of the castings, the flow rate of the […]

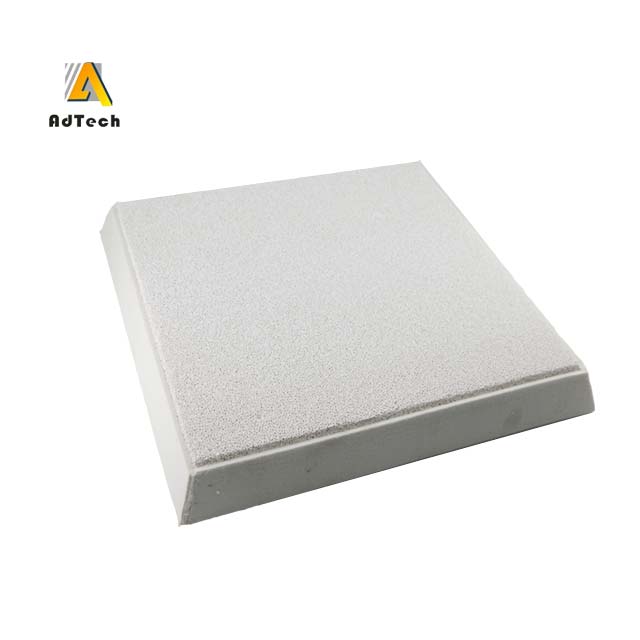

Cast ceramic foam filter is an effective molten metal filter. Its three-dimensional connected network structure and high porosity have many advantages, such as large area slag collection. The inner surface has a large filtering area. The ceramic foam filter is one of the sizes with small flow resistance and good filtering effect, and the size […]

Alumina ceramic filters use a three-dimensional network structure and organic foam with connected pores as a carrier to invade the thixotropic alumina material slurry. Using a fully automatic extrusion process with square correction center distance, the slurry is evenly spread on the foam skeleton of the carrier, and baked and cured at a high temperature […]

A degasser system using a rotor in a stator or a molten aluminum refining system for gas removal will generally involve the use of one or more injectors or injection devices, such as a rotating rotor device, to inject inert gas. The injector usually introduces an inert gas (such as argon) into the molten metal […]

In the processing of molten aluminum, it is desirable to remove certain gases and other materials or elements from the molten aluminum before further processing and depending on the specific application or process. The device or function can generally be called a degasser or degassing for molten aluminum. In the application of a degasser for […]

The molten metal filtration system is still an area of concern. Relative to some applications, some existing systems have various advantages and disadvantages. Therefore, there is still a need to make further contributions in this technical field. Casting processes (such as investment casting and other casting processes) produce parts by pouring a liquid (usually metal) […]

Investment casting is the process of forming metal or metal alloy products (also called castings) by solidifying molten metal. Precision casting is an important method for producing high-quality precision casting metal products in various industries. Castings usually contain unwanted materials called “inclusions.” The generation of inclusions can be attributed to the slag or scum material […]

The molten metal filtering device can prevent the molten metal from solidifying and clogging due to the oxide film entering the surface of the molten metal or the temperature drop of the filter medium itself. The molten metal filter medium is made of porous ceramic material in the shape of a flat plate. This filter […]