In the aluminum alloy casting process, the molten aluminum liquid is filtered by a filter bag and then cast into a mold for casting. Due to the fluctuation of the liquid level, the aluminum liquid enters the crystallizer and is filtered through the filter bag. Affected by the liquid level drop, when the liquid level […]

Aluminum silicate fiber plug is important for the casting process of aluminum and aluminum alloy rods. Its main function is to block aluminum liquid and control the flow of aluminum liquid in aluminum and aluminum alloy casting. AdTech tap out cone can withstand high temperature and corrosion, and has high toughness and low density. It […]

In the casting process of aluminum alloy, the aluminum water in the melting furnace needs to be injected into the crystallizer through the down injection pipe. However, during this process, the molten aluminum injected into the crystallizer will roll arbitrarily, resulting in oxidized slag inclusions. And it will result in uneven distribution of the molten […]

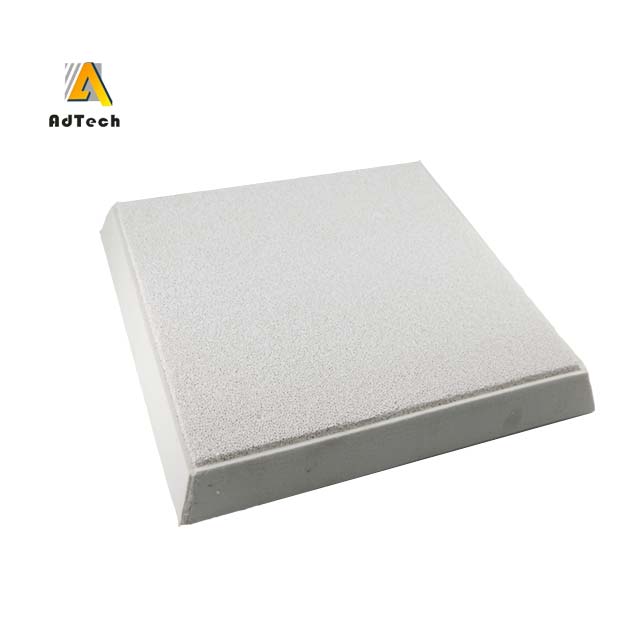

The main factor that affects the ceramic filtration accuracy is the maximum pore diameter of porous ceramic filter elements. For the same fluid medium, the smaller the pore size, the higher the filtration accuracy, and vice versa. Secondly, the working pressure also has a slight effect on the filtration accuracy. The larger the pore diameter […]

The manufacture of aluminum alloys meets the requirements for higher purity of cast metals to improve the quality of the final products (foils, blocks, ingots, rods, profiles). Therefore, molten aluminum filtration is the most effective method, which can reduce the manufacturing waste rate of the final product and improve its quality. Pollution of hard metals […]

Fluxes for aluminum alloys are generally composed of chlorides and fluorides of alkali metals and alkaline earth metals, and their main components are KCl, NaCl, CaF, Na3 AlF6, Na2 SiF6, etc. The physical and chemical properties of the flux (melting point, density, viscosity, volatility, hygroscopicity, and interface with oxides) play a decisive role in the […]

Porous materials play an important role in cushioning, vibration damping, heat insulation, noise reduction, filtration, etc. High-porosity solids have high rigidity and low density. So natural porous solids are often used as structures, such as bones. While the use of porous ceramic material by humans has not only structural aspects but also many functional uses. […]

When the content of slag and gas in the melt of aluminum and aluminum alloy is too high, it will greatly increase the probability of metallurgical defects, such as porosity and inclusions in the slab. In turn, it reduces the strength and plasticity of the material and affects the surface quality of the product. When […]

With the rapid development of the automotive industry, the output of aluminum alloy castings is growing rapidly. A large number of casting waste products caused by improper treatment of aluminum alloy melts is a problem, the aluminum alloy casting manufacturers urgently need to solve. In recent years, the research of rotating degassing system for aluminum […]

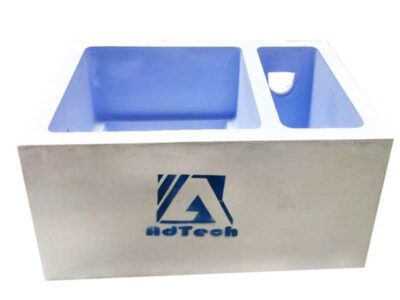

Aluminum industrial filter box designed for use in the aluminum industry as a working lining for aluminum water transfer equipment, such as aluminum flow troughs, filter boxes, etc., in direct contact with aluminum water. It also can be used as aluminum water holding furnace, lining and aluminum water bag, lining material. Aluminum Filter Box The […]