The Insulation Cover Agent is used to reduce oxidation and hydrogen adsorption by forming a melting barrier on the alloy surface, and to solve these problems by reducing the thickness of the scum shell. These fluxes can reduce the amount of suspended liquid metal by 60%-80%. No matter which casting process is used, the cast […]

In aluminum and aluminum alloy melts, Aluminum Refining Fluxes are substances, which can remove gases, inclusions, and harmful elements from the melt through physical and chemical interactions. Commonly used aluminum alloy refining agents, according to their functions, include covering agent, degassing agent, refining agent (also known as the composite purifying agent), slagging agent (also known […]

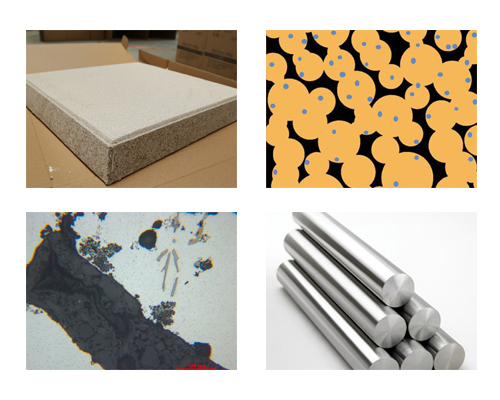

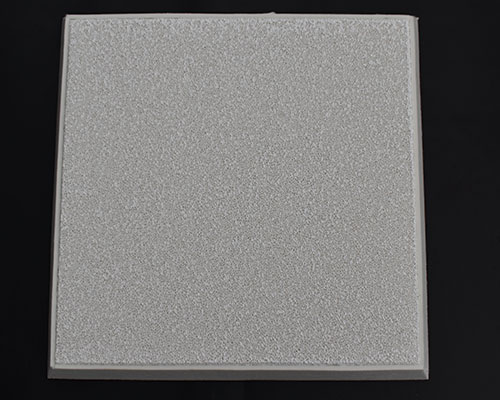

The aluminum foundry ceramic foam filters (CFF) are brittle and fragile, so the grains of foam filter are easily broken off. Sample specimens obtained from the filters are therefore irregularly shaped, as well as porous. The structure of the CFF creates a unique, tortuous path for the fluid to flow, which captures inclusions and allows […]

Ceramic Foam Filters (CFF) for metal filtration have been used commercially in the foundry industry for more than forty years, are used to produce high-quality aluminum castings for applications such as the aerospace industry. In recent years, for the non-ferrous metal industry, ceramic foam filters for metal filtration have become more and more important in […]

Ceramic filters mainly include foam ceramic filter, bonded ceramic particle filter, and rigid ceramic filter. Ceramic foam filter is widely used in general aluminum castings. Ceramic foam filter has high porosity and a large adsorption area. They have a good filtering effect on inclusions larger than 10 μm (for example, the efficiency of removing 40 […]

Refining fluxes for foundry are usually composed of alkali metal chlorides or alkaline earth metal chlorides, which are mixed to obtain a melting point below the operating temperature of the alloy-the melting point of a pure compound is usually quite high. Various methods can be used to incorporate the salt flux into the alloy: Before […]

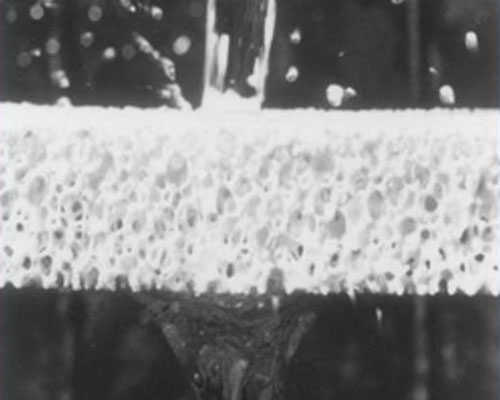

In order to ensure the full molten metal filtration, the ceramic foam filter must have a certain pressure head for starting the filtration to overcome the obstacle of surface tension. The pressure head size has a considerable effect on the start of the filter. Generally, it should be greater than 400 mm. The indenter should […]

Aluminum Ingot Foundry Filter is the third generation of porous ceramic filter newly developed after ordinary porous ceramic filter and honeycomb ceramic filter. Foam ceramic filter can form many small holes and many twists, and has many advantages such as high strength, high temperature resistance, good filtering, and adsorption performance. The pore size of the […]

Aluminum Foundry Molten Metal Filtration effectively reduces the level of inclusions and the subsequent notch effect caused by inclusions. Traditional techniques for removing inclusions are ineffective, and the use of metal or fiber screens is not enough to keep metals away from harmful non-metals. The aluminum foundry uses a ceramic foam filter for molten metal […]

Refractory Vacuum Formed Shapes are used in the continuous casting aluminum profile industry and aluminum alloy manufacturing industry, and can achieve significant economic benefits. The Refractory Vacuum Formed Shapes produced by AdTech is made of high-aluminum fiber, from the original manual process to a vacuum suction filtration automatic equipment molding process, with high production efficiency, […]